איך להבטיח את קיימותו של צינורות פליז באטמוספרות קשות

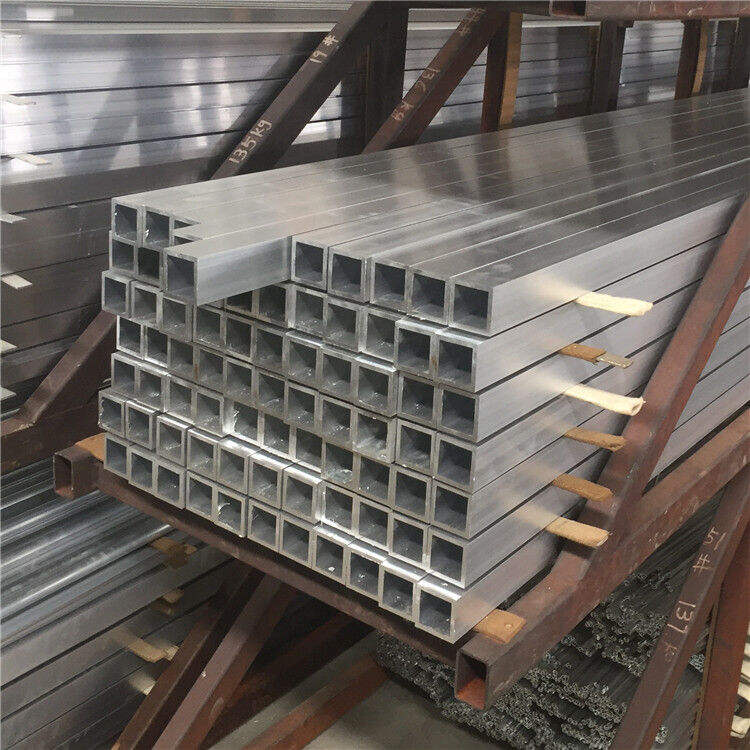

הארכת חיי המדף של רכיבי פליז בתנאי סביבה קשים עמידותם של צינורות פליז בתנאי תעשייה קשוחים נעשתה קריטית יותר עם הלחצים שהתפתחו בתנאי הפעלה. ממכשור תעשייתי כימי ועד צינורות תובלה באטמוספרות קשות, חומרים אלו נדרשים לעמוד בדרישות קשות. באמצעות טכניקות טיפול מתקדמות, חיפויים הגנתיים ועיצובים מותאמים, ניתן להרחיב משמעותית את חיי השירות של רכיבי פליז, תוך חיסכון בעלות תחזוקה וירידה בהפסדי זמן תפעול.

הצג עוד