מוט פליז מותג الصين

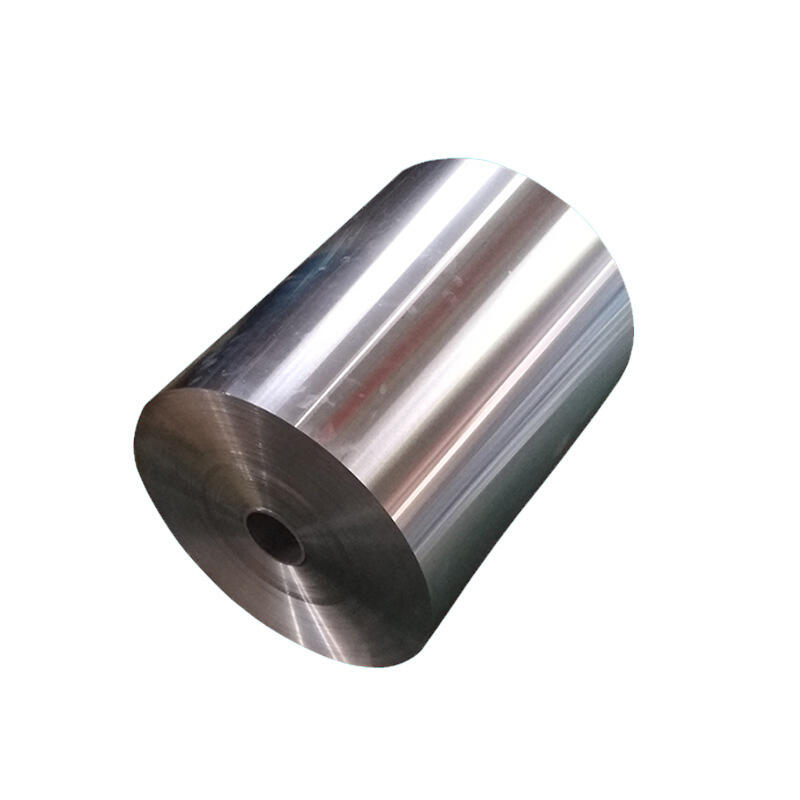

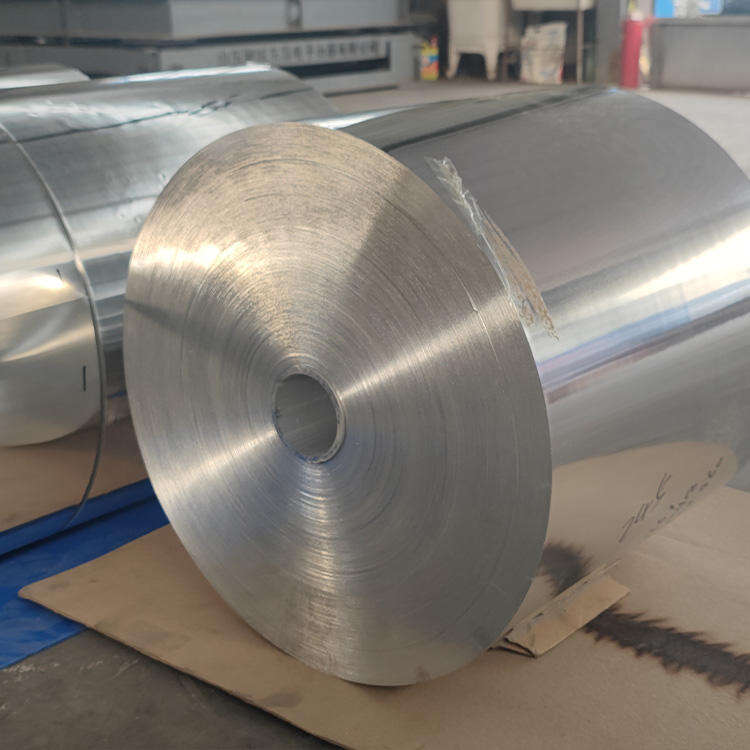

قضبان ממתכת נержשת המיוצרת בסין מייצגות אבן יסוד בייצור התעשייתי המודרני, ומציעות איכות יוצאת דופן ותכליתיות בapplications רבות. מוצרים אלו הנדסיים בדיוק עוברים תהליכי בקרת איכות קפדניים, ומכילים דרגות שונות, כולל 304, 316 ו-201 כדי לענות על דרישות תעשייה מגוונות. יצרנים סיניים משתמשים בטכנולוגיות ייצור מתקדמות, כולל יציקה רציפה ותהליכי גלגול חם, מה שמבטיח תכונות חומר אחידות לאורך القضبان. القضبان זמינות בצורות שונות, כולל עגולות, מרובעות, מחומשות ושטוחות, עם קטרים בין 3 מ"מ ל-500 מ"מ. המוצרים מציגים התנגדות מצוינת לאיחוי, חוזק מתיחה ניכר וסיום שטח מפואר, מה שעושה אותן אידיאליות לתעשייה הבנאייה, הרכב, תעופה וفضה, ותעשייה כימית. תהליך הייצור כולל עמידה קפדנית בסטנדרטים בינלאומיים כמו ASTM, AISI ו-JIS, מה שמבטיח תאימות לשוק העולמי. מערכות בקרת איכות מודרניות, כולל ניתוח ספקטרוגרפי ובוחן על-קולי, מבטיחות את שלמות מבנית והרכב כימי של כל משלוח. القضبان מציגות תכונות מכאניקליות נוצצות, כולל חוזק נטיה גבוה, דוקיוליות מצוינת והתנגדות איחוי יוצאת דופן, מה שעושה אותן מתאימות ליישומים קשים בסביבות קשות.