The versatility of aluminum bar products in modern industries

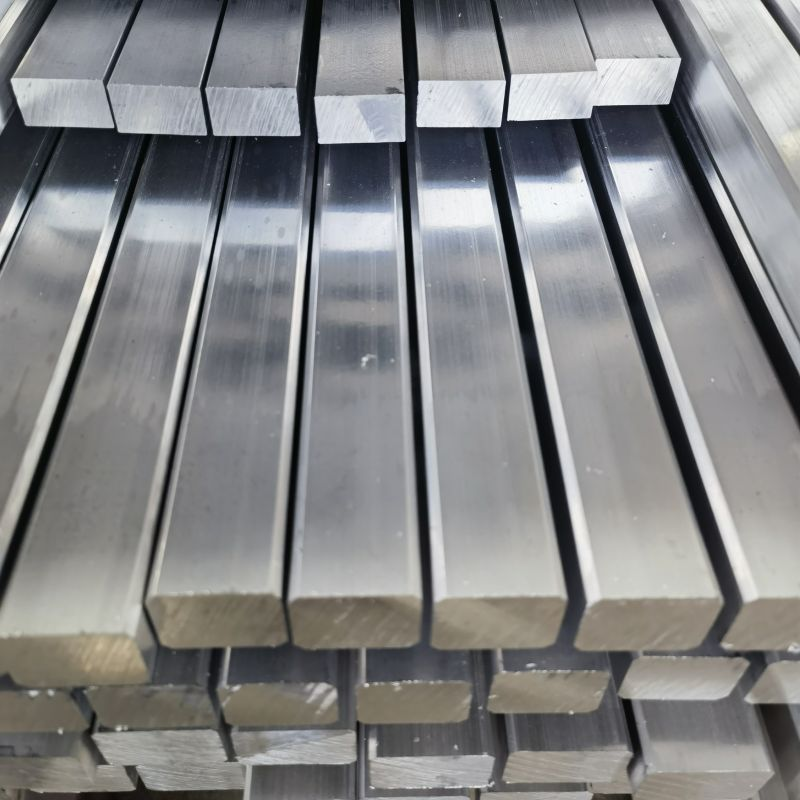

Aluminum bar products are widely used across numerous industries due to their unique combination of strength, lightweight properties, and corrosion resistance. These products offer excellent machinability and thermal conductivity, making them a preferred material for both structural and functional applications. Companies that integrate aluminum bar products into their manufacturing processes often see improvements in efficiency, durability, and product quality. The broad applicability of aluminum bar products ensures they remain a critical resource in both traditional and emerging industrial sectors.

Aerospace and aviation applications

Lightweight structures with aluminum bar products

In the aerospace industry, weight reduction is a crucial factor. Aluminum bar products provide the necessary structural strength while minimizing weight, helping improve fuel efficiency and aircraft performance.

Corrosion resistance for long-term performance

Aluminum bar products resist corrosion from moisture and environmental exposure, ensuring safety and longevity in aircraft components. This makes them highly valuable in aerospace engineering.

Automotive and transportation benefits

Enhanced vehicle efficiency

Automotive manufacturers use aluminum bar products to reduce overall vehicle weight, which contributes to better fuel economy and lower emissions. Aluminum bars also allow for precision engineering in complex components.

Durability and crashworthiness

Aluminum bar products offer mechanical strength and energy absorption capabilities, enhancing the safety and durability of vehicles in demanding operating conditions.

Construction and infrastructure uses

Structural applications of aluminum bar products

Aluminum bar products are used extensively in construction for frameworks, supports, and architectural elements. Their lightweight nature simplifies handling and installation while maintaining structural integrity.

Resistance to environmental factors

Corrosion resistance makes aluminum bar products suitable for outdoor and marine environments, extending the lifespan of bridges, buildings, and infrastructure projects.

Electronics and electrical industries

Conductivity advantages of aluminum bar products

Aluminum bar products have excellent electrical conductivity, making them suitable for use in electrical systems, power distribution, and electronic components.

Heat dissipation and thermal management

Aluminum bar products efficiently dissipate heat, which is critical in electronics and electrical applications. This property ensures devices operate safely and maintain performance over time.

Manufacturing and machinery applications

Machinability and precision

Aluminum bar products are easy to machine, allowing manufacturers to produce precise components for machinery and equipment. This adaptability supports innovation and complex design requirements.

Lightweight and robust components

Machinery benefits from aluminum bar products due to their combination of low weight and high strength. This improves operational efficiency and reduces wear on moving parts.

Marine and transportation infrastructure

Corrosion resistance in harsh environments

Aluminum bar products are ideal for marine applications, including shipbuilding and offshore structures. Their resistance to saltwater corrosion ensures longevity and reduces maintenance costs.

Strength-to-weight ratio advantages

In ships and marine platforms, aluminum bar products offer structural strength without significantly increasing weight, improving overall performance and safety.

Renewable energy and power sectors

Wind and solar energy applications

Aluminum bar products are used in wind turbines, solar panel frameworks, and related infrastructure. Their durability and lightweight properties enhance energy efficiency and system stability.

Electrical and thermal management benefits

The combination of electrical conductivity and thermal performance makes aluminum bar products suitable for power generation and energy distribution applications.

Choosing the right aluminum bar products

Material grades and specifications

Different industries require specific grades and dimensions of aluminum bar products. Selecting the right alloy and temper ensures optimal performance in each application.

Supplier reliability and quality assurance

Partnering with suppliers who provide consistent quality aluminum bar products ensures performance reliability, reduces downtime, and minimizes defects in end products.

FAQ

Which industries use aluminum bar products the most

Aerospace, automotive, construction, electronics, and marine industries are among the top users of aluminum bar products due to their strength, lightweight, and corrosion resistance.

How do aluminum bar products improve vehicle efficiency

By reducing the weight of automotive components, aluminum bar products enhance fuel efficiency and lower emissions while maintaining structural strength.

Are aluminum bar products suitable for outdoor construction

Yes, aluminum bar products resist corrosion and environmental damage, making them ideal for outdoor construction and infrastructure projects.

What factors should be considered when selecting aluminum bar products

Material grade, mechanical properties, corrosion resistance, and supplier quality are key factors to ensure optimal performance in specific industry applications.

Table of Contents

- The versatility of aluminum bar products in modern industries

- Aerospace and aviation applications

- Automotive and transportation benefits

- Construction and infrastructure uses

- Electronics and electrical industries

- Manufacturing and machinery applications

- Marine and transportation infrastructure

- Renewable energy and power sectors

- Choosing the right aluminum bar products

- FAQ