Wide range of seamless & welded stainless steel tubes in 304, 316L, duplex and more for industrial & architectural use

ISO 9001–certified factory with global export experience, large ready stock and custom cutting / fabrication

Strict quality control to international standards (ASTM, ASME, EN, DIN, JIS) for long-term corrosion and pressure performance

1. Product Overview

As a professional stainless steel tube supplier, we provide a full range of seamless and welded stainless steel tubes and pipes for industrial, commercial, and architectural applications.

Our stainless steel tubes offer:

With advanced production equipment and rich manufacturing experience, we can customize dimensions, grades and finishes according to specific project requirements and ensure that every tube meets international standards.

| Item | Description / Range |

|---|---|

| Material | Stainless steel (304, 304L, 316, 316L, 2205 Duplex, 321, 904L, etc.) |

| Dimension Definition | Outer Diameter (OD) × Wall Thickness (WT) × Length |

| Manufacturing Method | Seamless or Welded |

| Standards | ASTM, ASME, EN, DIN, JIS and other international standards |

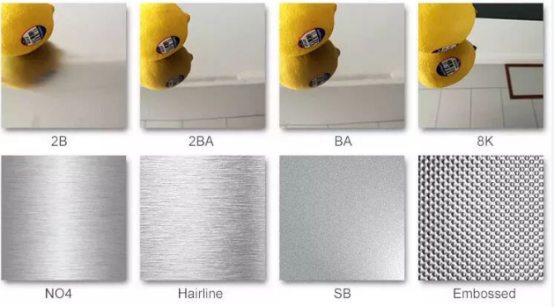

| Surface Treatment | Annealed, Pickled, Bright Annealed, Polished (including mirror finish) |

| Applications | Industry, construction, chemical, food processing, automotive, marine |

| Tube Type | Key Features & Typical Applications |

|---|---|

| Seamless Tube | High pressure capability, no weld seam, excellent integrity. Ideal for chemical processing, oil & gas, boilers, heat exchangers. (e.g. ASTM A269 / A312) |

| Welded Tube | Cost-effective, accurate dimensions, good surface finish. Suitable for decorative, structural, sanitary and lower-pressure fluid systems. (e.g. ASTM A249 / A270) |

| Shape Type | Typical Uses |

|---|---|

| Round Stainless Steel Tubes | General piping, process lines, mechanical structures, heat exchangers |

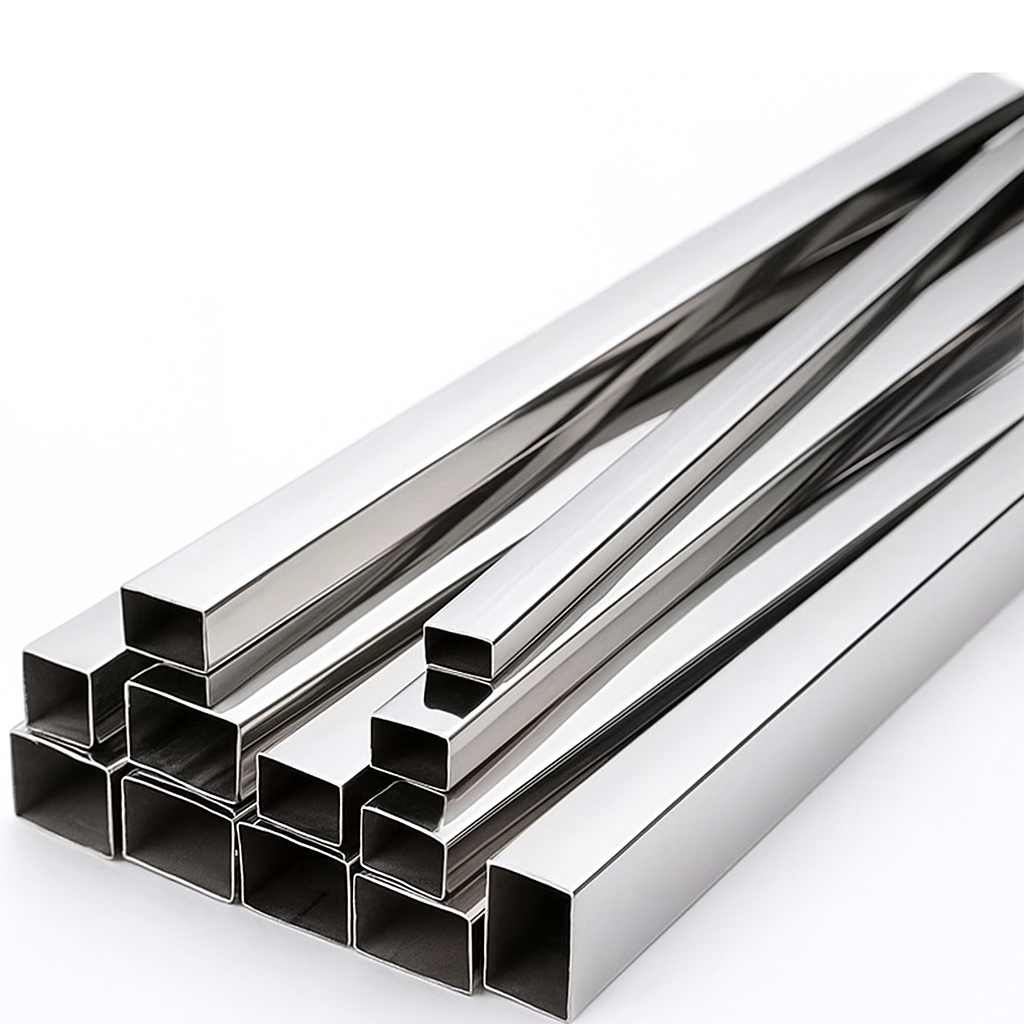

| Square Stainless Steel Tubes | Frames, supports, architectural and decorative structures |

| Rectangular Stainless Tubes | Structural components, railings, furniture and façade systems |

| Oval Stainless Steel Tubes | Handrails, exhaust systems, design-focused architectural components |

Size ranges (OD / width–height / WT) can be customized within common small, medium and large series according to project standards.

| Grade | UNS No. | Main Properties & Applications |

|---|---|---|

| 304 / 304L | S30400 / S30403 | General-purpose stainless steel, good corrosion resistance & formability. Used in food, water, general industry, architecture. |

| 316 / 316L | S31600 / S31603 | Improved pitting and chloride resistance. Ideal for marine, chemical, pharmaceutical and hygienic systems. |

| Duplex 2205 | S31803 / S32205 | High strength and superior resistance to stress corrosion cracking. Used in offshore, desalination, and demanding structural systems. |

| Others | 321, 904L, Super Duplex 2507, etc. | Available for projects requiring higher corrosion resistance or special properties. |

| Parameter | Range | Notes |

|---|---|---|

| Outer Diameter (OD) | 6 mm – 630 mm (1/8" – 24") | Full metric and imperial sizes available |

| Wall Thickness (WT) | 0.5 mm – 50 mm (Sch 5S – Sch 80 and above) | Custom wall thickness and tolerance on request |

| Length | 3 m, 6 m, or custom cut lengths | Cut-to-length service reduces on-site waste |

Q1: What is the difference between a stainless steel tube and a stainless steel pipe?

A: In many industries the terms are used interchangeably, but generally “pipe” is defined by nominal pipe size and schedule and is mainly used for fluid transport, while “tube” is defined by exact outer diameter and wall thickness and is often used in structural, mechanical and precision applications.

Q2: What is the difference between seamless and welded stainless steel tubes?

A:

Seamless tubes are produced without a weld seam and are preferred in high pressure, high temperature and critical service applications such as chemical, oil & gas and boiler systems.

Welded tubes are made from strip or coil welded into a tube. They are more economical, have good dimensional accuracy and are widely used in decorative, structural and low- to medium-pressure systems.

Q3: How should I choose between 304 and 316L stainless steel tubes?

A:

Choose 304 / 304L if the environment is relatively mild (indoor, normal industrial, general food processing) and cost is a key factor.

Choose 316 / 316L when the environment contains chlorides or stronger corrosive media, such as marine, coastal, chemical, and pharmaceutical applications. 316L has lower carbon content and better resistance to intergranular corrosion, especially after welding.

Q4: What surface finishes are available for your stainless steel tubes?

A: We offer annealed & pickled (AP), bright annealed (BA), and mechanically polished surfaces including satin and mirror finishes. Sanitary and high-cleanliness systems usually select BA or polished tubes, while industrial pipelines often use AP finish.

Q5: What is your typical lead time for custom stainless steel tube orders?

A: Lead time depends on grade, size, quantity and processing requirements. For standard sizes in stock, shipment can be arranged quickly; for customized sizes or special grades, production usually takes several weeks. Your exact lead time will be confirmed after reviewing your specifications.

Q6: How can I get a stainless steel tube price quote?

A: Please provide the following information for an accurate quotation:

Grade (e.g. 304, 316L, 2205, etc.)

Tube type (seamless or welded)

OD, wall thickness and required length

Quantity and destination port

Once we receive your details, our sales team will respond with a detailed price and delivery plan.