304-2B Stainless Steel Sheet: Properties, Uses, and Buying Guide

✨ Properties, Applications & Practical Buying Guide

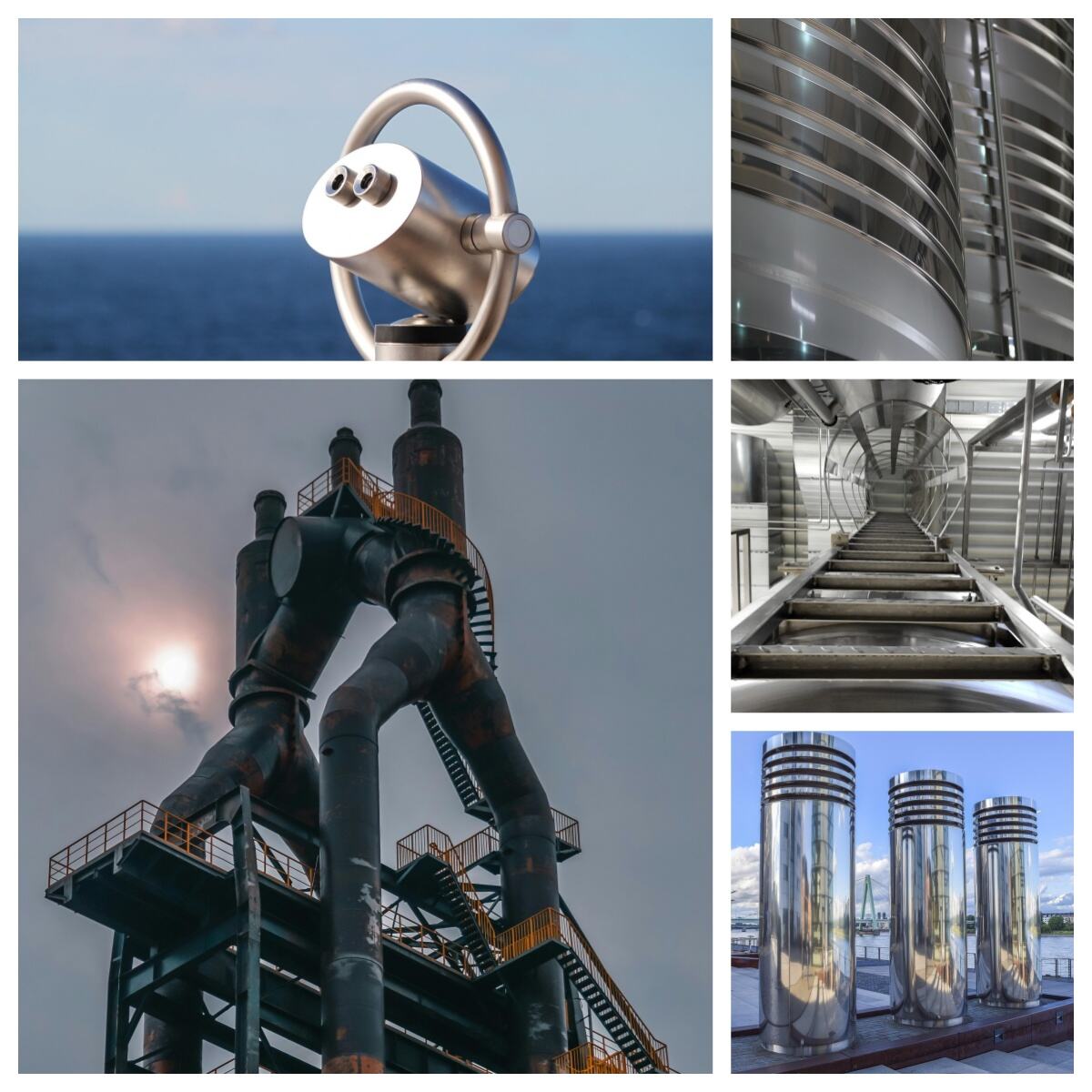

304-2B Stainless Steel Sheet is one of the most popular stainless steel flat products in global B2B trade. It offers a strong balance of corrosion resistance, clean surface appearance, and easy fabrication, making it suitable for a wide range of industrial and commercial uses.

This article explains the material in a clear, structured way—covering what it is, how it performs, where it’s used, and how to choose the right specification. The language stays simple and practical, while still meeting professional and SEO standards.

🔍 What Is 304-2B Stainless Steel Sheet?

✔ Grade 304 Stainless Steel Explained

Grade 304 is an austenitic stainless steel alloyed mainly with chromium and nickel. This structure helps the material resist rust, handle forming operations, and stay stable across many environments.

Because of its versatility and cost efficiency, grade 304 is often considered the standard stainless steel for general-purpose applications.

✔ What Does “2B Finish” Mean?

The 2B finish is a smooth, slightly reflective surface created through:

Cold rolling

Annealing & pickling

Light skin-pass rolling

It looks clean and uniform, without being mirror-bright. This finish is widely accepted for industrial, food-grade, and architectural uses.

⭐ Key Advantages of 304-2B Stainless Steel Sheet

✔ Good corrosion resistance in most indoor and outdoor environments

✔ Excellent formability for bending, stamping, and rolling

✔ Easy welding using standard methods

✔ Smooth, hygienic surface that’s easy to clean

✔ Cost-effective compared with higher-alloy stainless steels

⚠️ Note: It is not recommended for strong acids or high-chloride (marine) environments.

🏗 Typical Applications

🏢 Construction & ArchitectureWall panels Decorative trims Elevator interiors Protective covers |

🍽 Food & Beverage EquipmentKitchen worktables Food processing machinery Storage tanks Catering equipment |

🏭 Industrial EquipmentMachine housings Chemical equipment (mild environments) Fabricated metal parts |

🚗 Automotive & TransportInterior panels Brackets Trim components |

🧪 Chemical Composition (Typical)

| Element | Content (%) |

|---|---|

| Chromium (Cr) | 18.0 – 20.0 |

| Nickel (Ni) | 8.0 – 12.0 |

| Carbon (C) | ≤ 0.08 |

| Manganese (Mn) | ≤ 2.00 |

| Silicon (Si) | ≤ 0.75 |

| Iron (Fe) | Balance |

👉 This composition gives 304-2B Stainless Steel Sheet its stable corrosion resistance and good processing performance.

⚙️ Mechanical Properties (Typical)

| Property | Value |

|---|---|

| Tensile Strength | ≥ 515 MPa |

| Yield Strength (0.2%) | ≥ 205 MPa |

| Elongation | ≥ 40% |

| Hardness | Moderate (good for forming) |

✔ Suitable for both structural use and deep fabrication

🔬 Physical Properties

| Property | Value |

|---|---|

| Density | ~8.0 g/cm³ |

| Melting Range | 1400–1450 °C |

| Magnetic Behavior | Non-magnetic (annealed) |

📏 Available Sizes & Specifications

Common Supply Range

| Item | Standard Range |

|---|---|

| Thickness | 0.3 – 6.0 mm |

| Width | 1000 / 1219 / 1500 mm |

| Length | 2000 / 2438 / 3000 mm |

| Surface Finish | 2B (others optional) |

| Edge | Mill edge / Slit edge |

✔ Custom sizes and tighter tolerances are usually available on request.

Standards Commonly Used

ASTM A240 / A480

JIS G4304

EN 10088

🏭 How 304-2B Stainless Steel Sheet Is Made

🔹 Cold Rolling

Improves thickness accuracy and surface smoothness.

🔹 Annealing

Restores ductility and improves corrosion resistance.

🔹 Pickling & Skin Pass

Removes scale and creates the final uniform 2B surface finish.

🛒 How to Choose the Right Material

✅ Match the Application

Indoor use, food contact, or decorative panels may require different thicknesses or flatness levels.

✅ Check Certificates

Mill Test Certificates (MTC) such as EN 10204 3.1 confirm material quality.

✅ Consider Fabrication Needs

Deep drawing, polishing, or welding may need tighter chemical control and better flatness.

❓ FAQ – 304-2B Stainless Steel Sheet

❓ What’s the difference between 2B and BA finish?

2B is smooth and lightly reflective, while BA is brighter and more mirror-like. 2B is more common and cost-effective.

❓ Is 304-2B stainless steel food safe?

Yes. It is widely used in food and beverage equipment when produced to standard specifications.

❓ Can it be used outdoors?

Yes, in most environments. Extra protection may be needed in coastal or high-chloride areas.

❓ How should stainless steel sheets be stored?

Store them dry, clean, and away from carbon steel to avoid surface contamination.