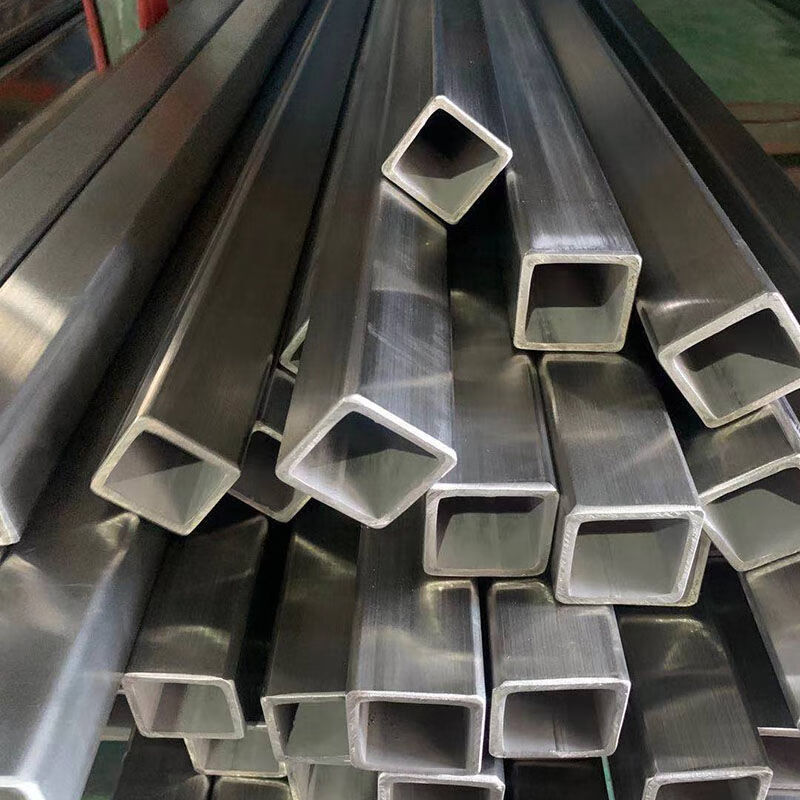

popular stainless steel bar

Stainless steel bars represent a fundamental component in modern manufacturing and construction, characterized by their exceptional durability and versatile applications. These cylindrical metal products are manufactured through advanced metallurgical processes, combining chromium, nickel, and other alloying elements with steel to create a corrosion-resistant material. The bars come in various grades and dimensions, offering specific properties suitable for different industrial needs. Their primary functions include structural support in construction, component manufacturing in machinery, and specialized applications in the automotive and aerospace industries. The manufacturing process involves hot rolling or cold drawing techniques, ensuring precise dimensional accuracy and superior surface finish. These bars exhibit remarkable mechanical properties, including high tensile strength, excellent fatigue resistance, and outstanding temperature performance. Their non-magnetic properties and resistance to chemical corrosion make them particularly valuable in marine environments and chemical processing facilities. The material's ability to maintain its structural integrity under extreme conditions, combined with its long service life and minimal maintenance requirements, has established stainless steel bars as a preferred choice across multiple industries.