Outstanding high-temperature strength & creep resistance

Excellent fatigue performance for aerospace & power systems

ASTM compliant supply with custom cutting available

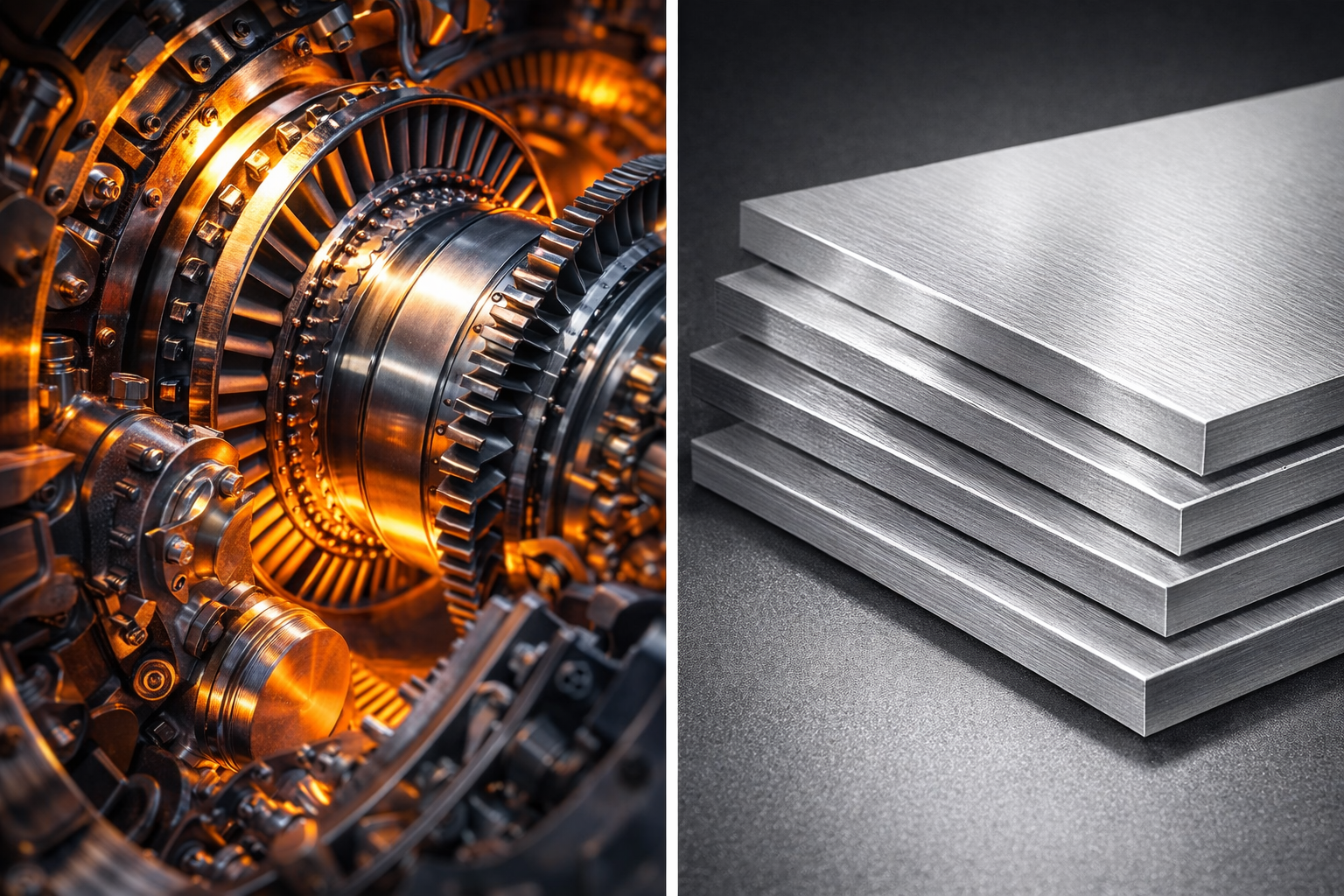

Inconel 718 Sheet is a precipitation-hardenable nickel-chromium alloy (commonly known as Alloy 718) engineered for high strength, fatigue resistance, and excellent performance in high-temperature service. Voyage Metal supplies Inconel 718 sheets and plates for aerospace, power generation, and demanding industrial applications.

Inconel 718 is strengthened primarily by age-hardening (precipitation strengthening), delivering exceptional tensile strength and creep resistance at elevated temperatures. It also offers strong resistance to oxidation and corrosion in harsh operating environments, making it a widely selected alloy for critical high-load parts.

| Item | Details |

|---|---|

| Material Grade | Inconel 718 / Alloy 718 |

| UNS No. | N07718 |

| Standard | ASTM B670 / ASME SB670 (Sheet/Plate) |

| Thickness Range | 0.5 mm – 50 mm |

| Width | ≤ 2000 mm |

| Surface Finish | 2B, BA, No.1, Polished |

| Supply Condition | Solution Treated / Aged (per request) |

| Services | Custom cutting, small trial orders, bulk supply |

| Industry | Common Uses |

|---|---|

| Aerospace | Engine components, turbine parts, high-strength structural assemblies |

| Power Generation | Gas turbine hardware, high-temperature fasteners, heat-resistant parts |

| Oil & Gas | High-load components exposed to heat, pressure and corrosive media |

| Industrial & Tooling | High-strength rings, fixtures, and demanding service parts |

Inconel 718 is widely selected for high-temperature, high-stress parts requiring excellent fatigue resistance, such as turbine and aerospace engine-related components.

We can supply solution treated material, or aged condition based on your specification and application needs. If you are unsure, share your service temperature and use-case, and we’ll recommend a suitable condition.

Yes. Voyage Metal supports custom thickness/width and precision cutting services to meet project requirements.

Send your required thickness, size, quantity, and destination port — we will reply with price and lead time quickly.

📩 Email: [email protected]

🌐 Website: www.voyagemetal.com

👉 Request Quote Now