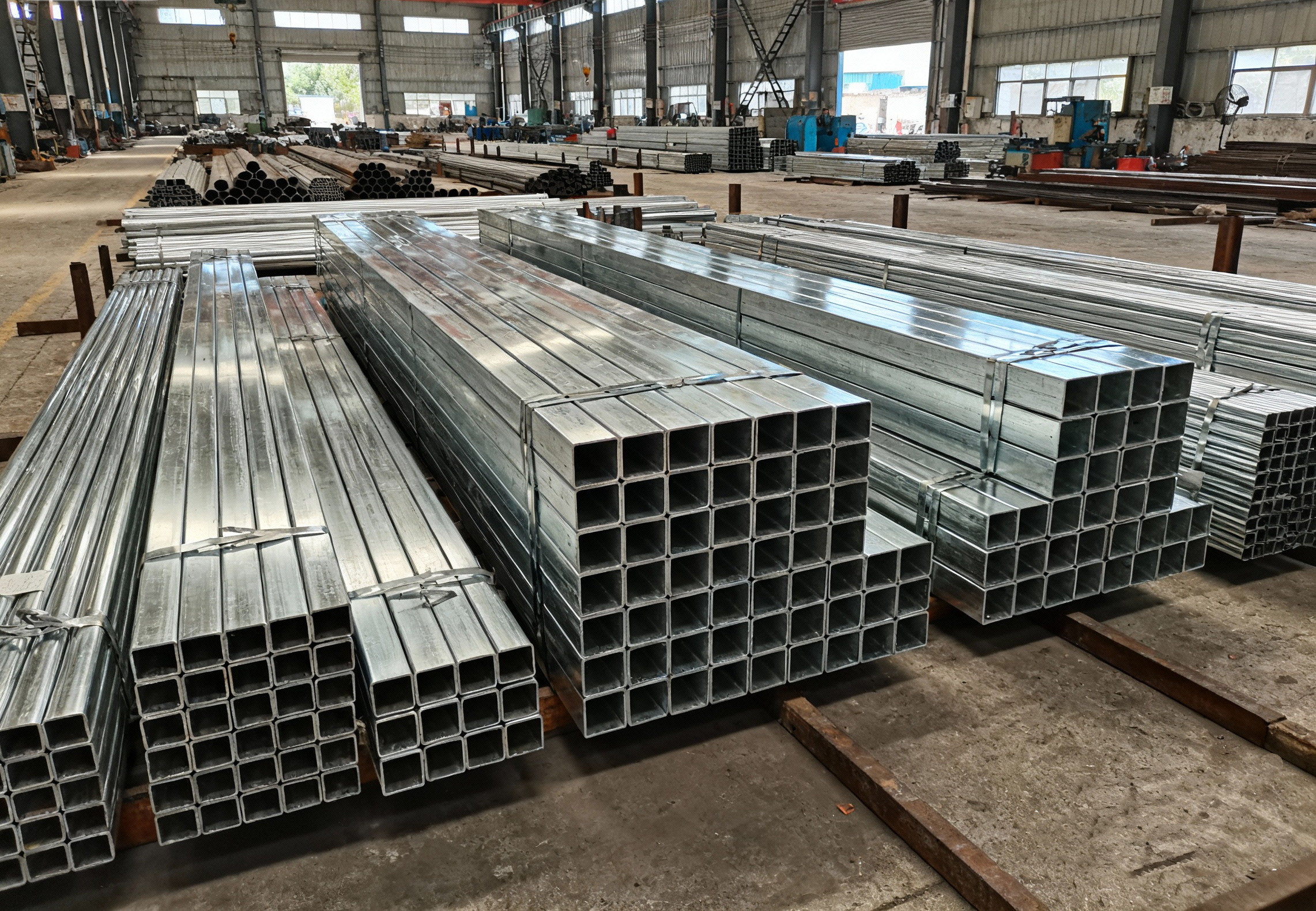

Our stainless steel square tubes are engineered for excellent mechanical strength, corrosion resistance, and long service life. Produced from high-grade stainless steel and manufactured under strict quality control, these square hollow sections are widely used in architectural frameworks, machinery fabrication, automotive parts, and decorative applications.

Our square stainless steel tubes are designed to deliver consistent performance in challenging environments such as coastal regions, chemical plants, food facilities, and high-humidity areas.

| Category | Details |

|---|---|

| Product Name | Stainless Steel Square Tube / Square Hollow Section |

| Grades Available | 201, 304, 304L, 316, 316L, 409, Duplex 2205 |

| Standards | ASTM, AISI, GB, JIS, EN, DIN |

| Dimensions | Side Width: 10–500 mm, Wall Thickness: 0.5–20 mm |

| Length | 1–12 m or customized |

| Finishes | 2B, BA, No.4, Mirror, Brushed, Pickled |

| MOQ | 1 MT |

| Packaging | Plastic film, woven bag, steel bundle, wooden crate |

Our production line ensures consistent quality across every batch. The process includes:

Selected stainless steel sheets or coils are inspected for chemical composition and surface quality.

Material is slit and cut to required widths depending on final tube size.

Coils are shaped into square profiles using advanced roll-forming equipment for stable geometry.

Laser welding or TIG welding guarantees strong seam integrity and minimal distortion.

Annealing improves corrosion resistance and restores ductility.

The tubes undergo polishing or pickling for optimal finish and improved cleanliness.

Dimensional checks, flattening tests, hydrostatic pressure tests, and mechanical strength evaluations are conducted to meet international standards.

Each batch is securely packed to prevent surface damage during handling and shipment.

Stainless steel square tubes are used in various industries due to their reliability and appearance. Here are some typical applications:

| Industry | Usage Examples |

|---|---|

| Construction & Architecture | Support frames, railings, window structures, decorative columns |

| Machinery & Equipment | Machine frames, conveyors, structural supports |

| Automotive | Exhaust systems, safety frames, chassis parts |

| Furniture Manufacturing | Table frames, storage racks, interior structures |

| Infrastructure | Bridges, walkway rails, public facilities |

| Energy & Utilities | Power equipment frames, heat exchanger supports |

| Medical & Food Processing | Hygienic structures, equipment frames, carts |

| Marine Engineering | Corrosion-resistant components, offshore structures |

| Aerospace | Lightweight structural elements |

If you need corrosion-resistant, load-bearing tubing for harsh environments, stainless steel square tubes offer unmatched longevity and performance.

✔ Full customization in dimensions, cutting, polishing & fabrication

✔ Strict inspection & documentation (MTC available for all orders)

✔ High export standards with professional packaging & global shipping

✔ Fast delivery and stable supply capacity

We supply stainless steel square tubes to distributors, contractors, engineering firms, and OEM manufacturers worldwide.