Aluminum coil is a metal sheet, which is melted from aluminum ingots, added with different alloys, and processed into aluminum coils through casting, hot rolling, cold rolling, annealing , cross-cutting and other processes.

Product general information

Product Name: |

1100 Aluminum Coil |

Thickness: |

0.3mm-20mm or as the customer’s request |

Width: |

60mm-2500mm or as the customer’s request |

Length: |

2000-12000mm, or custom made |

Surface: |

Polished,Mill Finished,anodized or power sprayed |

Technique: |

Cold Drawn, Hot Rolled |

Package: |

Export wooden pallets/cases |

Origin: |

Shanghai, China |

Commercial terms of products

Minimum Order Quantity: |

1 Ton |

Delivery Time: |

7-30 days |

Payment Terms: |

50% TT deposit, balance before shipment |

Supply Ability: |

Sea Transport, Land Transport, etc |

Other names:1060 Aluminum Roll

Description:

Aluminum coil is a metal sheet, which is melted from aluminum ingots, added with different alloys, and processed into aluminum coils through casting, hot rolling, cold rolling, annealing , cross-cutting and other processes. It has the characteristics of corrosion resistance, high strength , light weight , and good electrical and thermal conductivity . Widely used in construction , packaging , automobile manufacturing , electronics industry and other fields.

Chemical composition

Fe:≤0.35%

Mn:≤0.03%

Si:≤0.25%

Cu:≤0.05%

Al:Remainder

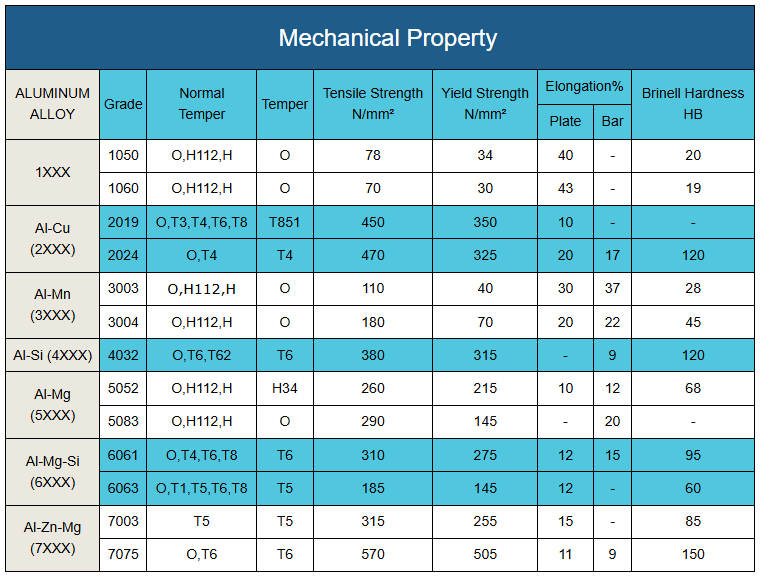

Mechanical properties :

Low strength: annealed tensile strength of about 95-120MPa, elongation of 20-30%, hardness of about 25-35HB, belonging to the typical “low strength, high plasticity” material.

Work hardening is obvious: after cold rolling, cold drawing and other cold processing, the strength can be increased to 130-160MPa, but the elongation decreases to 5-10%, which is suitable for strengthening simple structural parts through cold deformation.

Physical and Chemical Properties :Excellent corrosion resistance: the surface is easy to form a dense oxide film (Al₂O₃), in the atmosphere, fresh water and most of the neutral medium corrosion resistance is better than the alloy of aluminum, but only not resistant to strong acid, alkali corrosion.

Good electrical and thermal conductivity: electrical conductivity of about 60-65% of pure aluminum (pure aluminum is 100% IACS), thermal conductivity of about 200-210W / (m・K), suitable for low requirements of the conductive / thermal conductivity of the scene.

Outstanding processing performance: easy to cut, easy to weld (can be argon arc welding, resistance welding), and excellent plasticity, can be deep-drawn, stretching, bending and other complex molding (such as the production of aluminum foil, thin-walled containers).

Applications:

As a high-purity aluminum alloy with a purity of over 99.6%, 1060 aluminum is widely used in many fields. In the field of electronics and electric power, it is often used to make wires, cables and heat sinks, etc. The excellent electrical conductivity and thermal conductivity can efficiently transmit the current and emit heat in a timely manner to ensure the stable operation of electronic equipment. In the packaging industry, 1060 aluminum can be rolled into extremely thin aluminum foil due to its good plasticity, which can play a role in sealing and preserving freshness, and is easy to recycle, in line with the requirements of environmental protection. In addition, in the field of architectural decoration, it can be processed into a variety of decorative panels, lampshades, etc., the surface can be processed to present a beautiful metal texture, and light weight, easy to install.

Aluminum Series