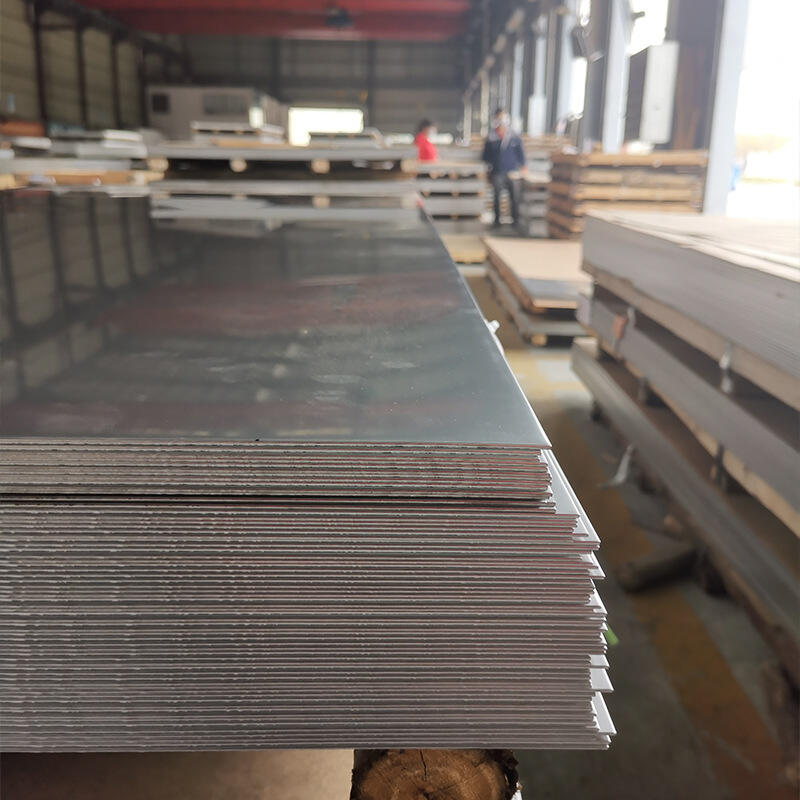

304L Hot Rolled Stainless Steel Plate is a low-carbon austenitic stainless steel widely used in industrial and structural applications. Thanks to its excellent corrosion resistance, strong weldability, and stable mechanical performance, it is a preferred material for pressure vessels, chemical equipment, and heavy fabrication projects.

Low-carbon austenitic stainless steel plate with strong weldability, reliable corrosion resistance, and stable performance for heavy fabrication and industrial equipment.

304L Hot Rolled Stainless Steel Plate is widely used for tanks, pressure components, frames, and structural parts where welding quality matters. Compared with standard 304, 304L uses lower carbon content to better protect corrosion resistance around weld zones. Hot rolling also supports thicker gauges and delivers good ductility for heavy fabrication.

| Item | Details |

|---|---|

| Grade | 304L (UNS S30403) |

| Equivalent | EN 1.4307 / JIS SUS304L |

| Standards | ASTM A240 / ASME SA240 / EN 10088-2 / JIS G4304 |

| Finish (Typical) | No.1 / 1D (Hot Rolled, Annealed & Pickled) |

| Test Certificate | EN 10204 3.1 (available) |

| Specification | Typical Range | Common Options | Customization |

|---|---|---|---|

| Thickness | 3.0 – 200 mm | 6, 8, 10, 12, 16, 20, 25 mm | ✅ Available |

| Width | 1000 – 2000 mm | 1000 / 1219 (4ft) / 1500 / 2000 mm | ✅ Available |

| Length | 2000 – 6000 mm | 2000 / 2438 (8ft) / 3000 / 6000 mm | ✅ Available |

| Edge | Mill Edge | — | ✅ Cutting/trim on request |

| Processing |

Cut-to-length / CNC / Plasma / Laser (by thickness) |

— | ✅ Available |

Values shown are typical limits/ranges used for specification. Mill test certificate data is supplied per heat/lot.

| Element | Requirement / Range (%) | Why It Matters |

|---|---|---|

| Carbon (C) | ≤ 0.03 | Lower C helps reduce sensitization after welding |

| Chromium (Cr) | 18.0 – 20.0 | Key for corrosion resistance |

| Nickel (Ni) | 8.0 – 12.0 | Improves toughness and formability |

| Manganese (Mn) | ≤ 2.00 | Supports strength and hot working |

| Silicon (Si) | ≤ 0.75 | Deoxidizer; supports processing |

| Phosphorus (P) | ≤ 0.045 | Controlled for toughness/weld quality |

| Sulfur (S) | ≤ 0.03 | Controlled for ductility and weldability |

| Nitrogen (N) | ≤ 0.10 | Helps strength; controlled for stability |

| Iron (Fe) | Balance | Base metal |

| Property | 304L Requirement | Notes |

|---|---|---|

| Tensile Strength | ≥ 485 MPa | Good load-bearing performance |

| Yield Strength (0.2%) | ≥ 170 MPa | Stable for structural parts |

| Elongation | ≥ 40% | Supports forming and fabrication |

| Hardness (Brinell) | ≤ 201 HB | Balanced for machining & forming |

| Item | 304L | 304 | Buyer Takeaway |

|---|---|---|---|

| Carbon | ≤ 0.03% | ≤ 0.08% | 304L is usually safer for welding-heavy projects |

| Corrosion resistance after welding | Better | Good | 304L helps keep weld zones more resistant |

| Strength | Slightly lower (typical) | Slightly higher (typical) | Choose based on weld + corrosion needs |

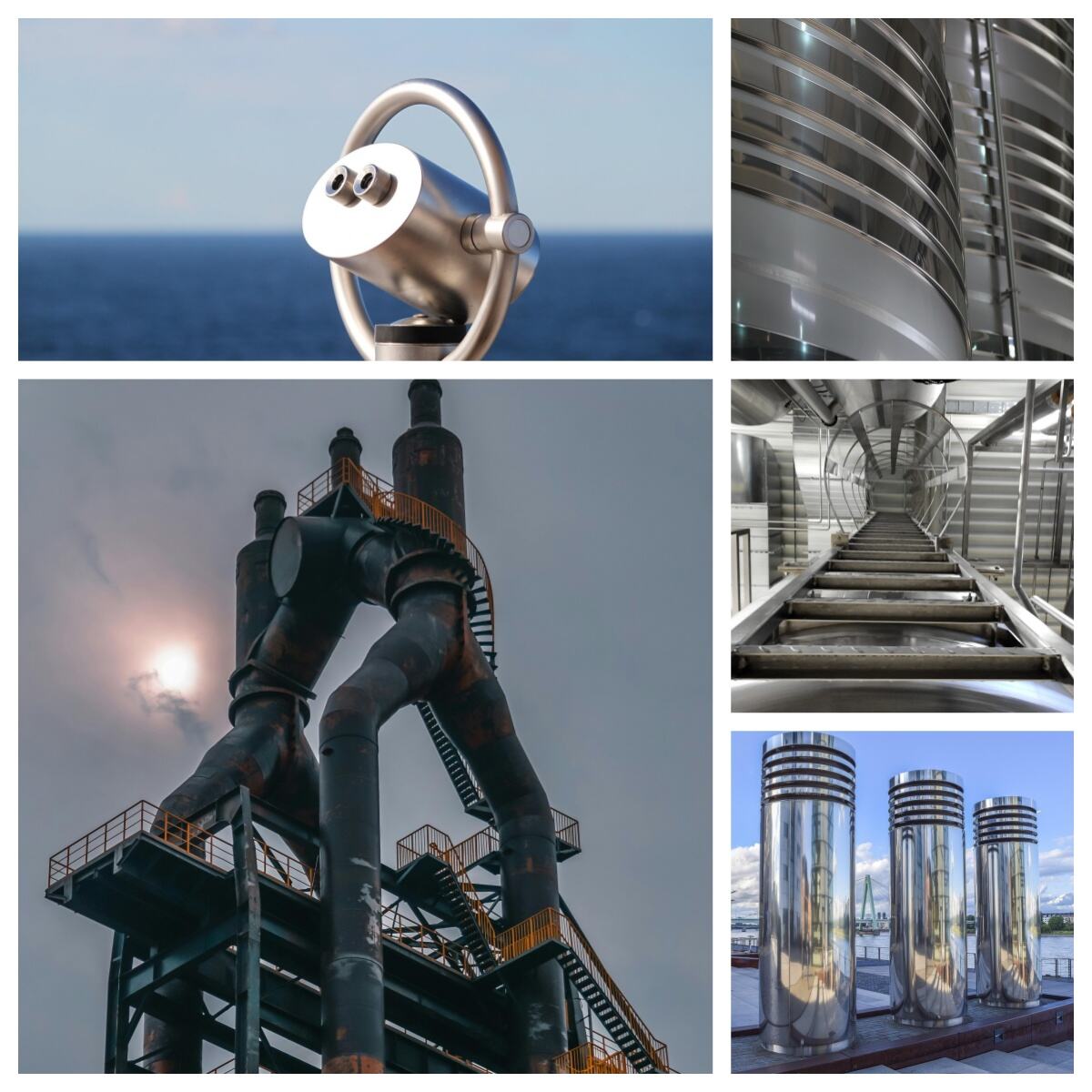

🏭 Chemical & Petrochemical

|

⚙ Industrial Equipment

|

🏗 Construction & Structural

|

🚢 Energy & Transport

|

Hot rolled plate works best for thicker gauges and heavy fabrication. Cold rolled products offer tighter thickness tolerance and a smoother surface, but they are usually thinner.

It is commonly used for tanks, pressure components, industrial frames, and structural parts where corrosion resistance and weld reliability matter.

Yes. The low carbon level helps reduce sensitization risk, so welded areas keep better corrosion resistance in many real-world applications.

Most hot rolled plates use a No.1 / 1D finish (hot rolled, annealed, and pickled). It is matte and suitable for industrial use.

Yes. Custom thickness/width/length and processing (cut-to-length, CNC, plasma/laser depending on thickness) can be arranged for project needs.

Share thickness × width × length, required standard, quantity, destination port, and any cutting/packing needs. Voyage Metal will respond with a competitive offer and lead time.