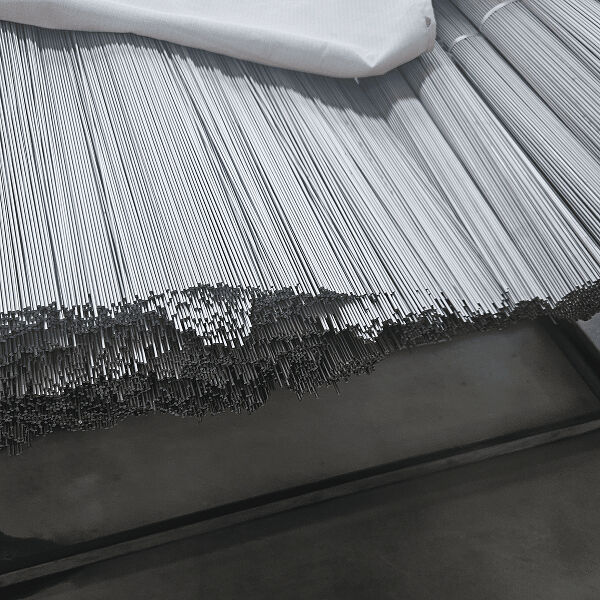

Manufacturing industries worldwide have increasingly turned to aluminum rods as a cornerstone material for diverse applications. These versatile metal components offer exceptional properties that make them indispensable for modern production processes. From aerospace to automotive sectors, aluminum rods provide manufacturers with lightweight yet durable solutions that meet stringent performance requirements. Understanding the comprehensive benefits of these materials enables companies to make informed decisions about their manufacturing strategies and optimize their production efficiency.

Superior Material Properties and Performance Characteristics

Exceptional Strength-to-Weight Ratio

The most significant advantage of aluminum rods lies in their remarkable strength-to-weight ratio, which surpasses many traditional materials used in manufacturing. This characteristic allows engineers to design components that maintain structural integrity while significantly reducing overall product weight. The lightweight nature of aluminum rods translates directly into energy savings during transportation and handling processes. Manufacturing facilities benefit from reduced machinery stress and lower operational costs when working with these materials.

High-strength aluminum alloys, particularly 6061 grades, demonstrate tensile strengths comparable to mild steel while weighing approximately one-third less. This property makes aluminum rods ideal for applications where weight reduction is critical without compromising performance. Industries such as aerospace, marine, and automotive manufacturing leverage this advantage to improve fuel efficiency and reduce environmental impact.

Outstanding Corrosion Resistance

Aluminum naturally forms a protective oxide layer that provides excellent corrosion resistance against environmental factors. This inherent property eliminates the need for additional protective coatings in many applications, reducing manufacturing costs and maintenance requirements. The corrosion resistance of aluminum rods ensures long-term durability and reliability in harsh operating environments.

Anodized aluminum rods offer enhanced protection through controlled oxidation processes that create thicker, more durable surface layers. This treatment further improves corrosion resistance while providing opportunities for aesthetic customization through color variations. Manufacturers benefit from extended product lifecycles and reduced warranty claims when utilizing these advanced aluminum rod solutions.

Manufacturing Efficiency and Processing Advantages

Enhanced Machinability and Fabrication

The excellent machinability of aluminum rods significantly improves manufacturing efficiency across various production processes. These materials cut cleanly with standard machining tools, requiring less cutting force and generating minimal heat during processing. This characteristic reduces tool wear and extends equipment life, resulting in lower operational costs and increased productivity.

Aluminum rods maintain dimensional stability throughout machining operations, ensuring consistent quality and precision in finished components. The material's predictable behavior during cutting, drilling, and shaping operations allows manufacturers to achieve tight tolerances with minimal waste. Advanced CNC machinery can process aluminum rods at higher speeds compared to steel alternatives, maximizing throughput and reducing production time.

Excellent Thermal and Electrical Conductivity

The superior thermal conductivity of aluminum rods makes them valuable for heat dissipation applications in manufacturing. This property enables efficient heat transfer, which is crucial for electronic components, heat exchangers, and thermal management systems. Manufacturers can design more compact and efficient cooling solutions using aluminum rod components.

Electrical conductivity properties of aluminum rods provide excellent performance in electrical applications while offering cost advantages over copper alternatives. The conductivity-to-weight ratio of aluminum exceeds that of copper, making it an attractive option for electrical transmission and distribution systems. Manufacturing facilities benefit from reduced installation costs and simplified structural requirements when using aluminum rod conductors.

Cost-Effectiveness and Economic Benefits

Material Cost Advantages

Aluminum rods offer significant cost advantages compared to alternative materials, particularly in high-volume manufacturing applications. The abundance of aluminum in the earth's crust ensures stable pricing and reliable supply chains for manufacturers. Market fluctuations typically have less impact on aluminum pricing compared to specialty metals and alloys.

The recyclability of aluminum rods contributes to long-term cost savings through material recovery and reuse programs. Manufacturing facilities can implement closed-loop recycling systems that reduce raw material costs while supporting environmental sustainability goals. The energy required to recycle aluminum is significantly lower than primary production, creating additional economic incentives for responsible material management.

Reduced Lifecycle Costs

The durability and longevity of aluminum rods translate into reduced lifecycle costs for manufactured products. Lower maintenance requirements and extended service life minimize replacement frequencies and associated downtime costs. Manufacturing companies benefit from improved customer satisfaction and reduced warranty expenses when utilizing high-quality aluminum rod components.

Transportation cost savings emerge from the lightweight properties of aluminum rod assemblies, reducing shipping expenses and handling requirements. These savings compound throughout the supply chain, from raw material delivery to finished product distribution. Manufacturers can pass these cost benefits to customers while maintaining competitive pricing strategies.

Environmental Sustainability and Green Manufacturing

Recyclability and Circular Economy Benefits

Aluminum rods support sustainable manufacturing practices through their infinite recyclability without quality degradation. This characteristic enables manufacturers to participate in circular economy initiatives while reducing environmental impact. The recycling process requires only five percent of the energy needed for primary aluminum production, significantly lowering carbon footprint.

Manufacturing facilities implementing aluminum rod recycling programs demonstrate environmental responsibility while achieving cost savings. The closed-loop nature of aluminum recycling ensures that material properties remain consistent through multiple use cycles. This sustainability aspect increasingly influences procurement decisions as companies prioritize environmental stewardship.

Energy Efficiency in Production

The processing efficiency of aluminum rods contributes to reduced energy consumption in manufacturing operations. Lower melting temperatures compared to steel alternatives decrease energy requirements for casting and forming processes. Manufacturing facilities benefit from reduced utility costs and improved environmental performance when utilizing aluminum rod materials.

The lightweight nature of aluminum rods reduces energy consumption throughout the manufacturing value chain, from material handling to final assembly. Automated production systems operate more efficiently when processing lighter materials, resulting in lower power consumption and extended equipment life. These energy savings contribute to improved profit margins and reduced environmental impact.

Applications Across Diverse Industries

Aerospace and Aviation Manufacturing

The aerospace industry relies heavily on aluminum rods for structural components, landing gear systems, and interior applications. The stringent weight requirements and safety standards in aviation make aluminum rods an ideal choice for critical components. Manufacturers can achieve significant fuel savings through weight reduction while maintaining required strength and safety margins.

Advanced aluminum alloy rods meet aerospace specifications for temperature resistance, fatigue performance, and dimensional stability. The predictable behavior of these materials under extreme conditions ensures reliable performance throughout aircraft service life. Manufacturing processes for aerospace applications benefit from the consistent quality and traceability of premium aluminum rod products.

Automotive and Transportation Industries

Automotive manufacturers increasingly utilize aluminum rods for chassis components, suspension systems, and body structures to improve fuel efficiency and performance. The corrosion resistance of aluminum rods extends vehicle life while reducing maintenance requirements. Crash safety performance benefits from the controlled deformation characteristics of aluminum rod assemblies.

Electric vehicle manufacturers particularly value aluminum rods for their lightweight properties and thermal management capabilities. Battery cooling systems and structural components benefit from the excellent heat dissipation and electrical properties of aluminum materials. The manufacturing efficiency gains from aluminum rod processing support rapid production scaling in the growing EV market.

FAQ

What are the main advantages of aluminum rods over steel alternatives in manufacturing

Aluminum rods offer several key advantages over steel alternatives including significantly lower weight, superior corrosion resistance, better thermal and electrical conductivity, and enhanced machinability. The strength-to-weight ratio of aluminum rods often exceeds steel while providing easier processing and reduced energy consumption during manufacturing. Additionally, aluminum rods require less maintenance and offer better recyclability compared to steel components.

How do aluminum rods contribute to sustainable manufacturing practices

Aluminum rods support sustainability through infinite recyclability without quality loss, requiring only five percent of the energy needed for primary production when recycled. Their lightweight properties reduce transportation energy consumption and carbon emissions throughout the supply chain. Manufacturing processes benefit from lower energy requirements due to reduced melting temperatures and improved processing efficiency compared to heavier alternatives.

What industries benefit most from using aluminum rods in their manufacturing processes

Industries that benefit most from aluminum rods include aerospace, automotive, marine, electronics, construction, and renewable energy sectors. These industries value the combination of lightweight properties, corrosion resistance, and excellent conductivity that aluminum rods provide. Applications range from structural components and heat exchangers to electrical conductors and precision machined parts across diverse manufacturing environments.

Are aluminum rods cost-effective compared to other materials in high-volume manufacturing

Yes, aluminum rods offer excellent cost-effectiveness in high-volume manufacturing through lower material costs, reduced processing time, extended tool life, and minimal waste generation. The recyclability factor provides additional cost savings through material recovery programs. Long-term benefits include reduced maintenance costs, lower transportation expenses due to weight savings, and improved energy efficiency throughout the manufacturing process.

Table of Contents

- Superior Material Properties and Performance Characteristics

- Manufacturing Efficiency and Processing Advantages

- Cost-Effectiveness and Economic Benefits

- Environmental Sustainability and Green Manufacturing

- Applications Across Diverse Industries

-

FAQ

- What are the main advantages of aluminum rods over steel alternatives in manufacturing

- How do aluminum rods contribute to sustainable manufacturing practices

- What industries benefit most from using aluminum rods in their manufacturing processes

- Are aluminum rods cost-effective compared to other materials in high-volume manufacturing