Aluminum bar is a kind of non-ferrous metal rod. It refers to a metal rod shape that is kneaded and processed from pure aluminum or aluminum alloy along its entire longitudinal length.

Product general information

Product Name: |

5083 Aluminum Bar |

Type: |

Round,Square,Hexagonal,Rectangle |

Diameter: |

Customized |

Length: |

3000mm, or custom made |

Service: |

Cutting, Anodizing, Custom-made. |

Technique: |

Cold Rolled, Extruded |

Package: |

Export wooden pallets/cases |

Origin: |

Shanghai, China |

Commercial terms of products

Minimum Order Quantity: |

1 Ton |

Delivery Time: |

7-30 days |

Payment Terms: |

50% TT deposit, balance before shipment |

Supply Ability: |

Sea Transport, Land Transport, etc |

Other names:5083 Aluminum Alloy Rod

Description:

Aluminum bar is a kind of non-ferrous metal rod. It refers to a metal rod shape that is kneaded and processed from pure aluminum or aluminum alloy along its entire longitudinal length. It has special chemical and physical properties. It is not only light in weight and hard in texture, but also has good ductility, electrical conductivity, thermal conductivity and heat resistance. Used in transportation, construction, industrial manufacturing and other fields.

Competitive Advantage:

High corrosion resistance: Especially in seawater and Cl⁻-containing environments, it has outstanding resistance to stress corrosion cracking. A dense oxide film can be formed on the surface, which is suitable for marine engineering and chemical equipment.

Non-heat treatment strengthening: Strength can only be improved by cold processing (such as rolling and stretching).

Excellent weldability: Suitable for argon arc welding (TIG/MIG), laser welding, and friction stir welding (FSW), with little strength loss after welding. No heat treatment is required after welding, suitable for large structural parts (such as hulls and storage tanks).

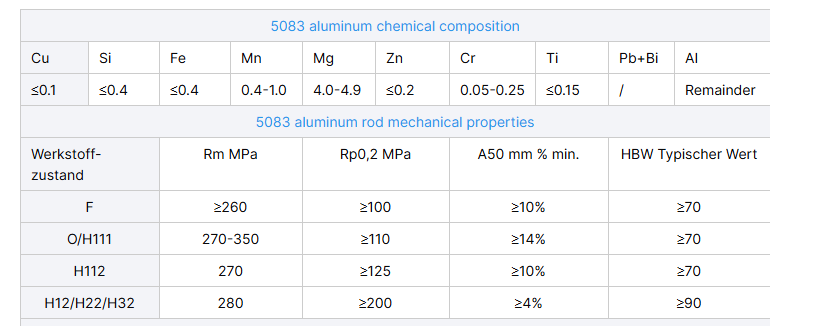

Medium strength: The tensile strength of the annealed state (O state) is about 270-350 MPa, and higher strength can be achieved after cold processing.

Good formability: The annealed state (O state) has high ductility and is suitable for stamping, bending and other processing.

Stable low temperature performance: Good toughness is maintained at low temperatures (such as -196℃).

Applications:

5083 aluminum rod is a typical rod-shaped product of 5xxx series aluminum alloy (with magnesium as the main alloying element). It has excellent corrosion resistance, medium strength and good machinability, especially in marine environment and low temperature conditions. Its application fields are wide, mainly concentrated in Marine engineering and shipbuilding.

5083 aluminum alloy's seawater corrosion resistance is its core advantage (magnesium content is about 4.0%-4.9%, forming a dense oxide film, strong resistance to pitting corrosion), so it is one of the preferred materials in the marine field:

Ship parts: such as hull frames, deck supports, cabin structural parts, propeller shaft system accessories, etc., can resist seawater immersion and salt spray erosion for a long time.

Offshore platform: brackets, railings, pipe brackets, etc. used for offshore platforms, adapting to harsh environments with high humidity and high salinity.

Seawater treatment equipment: pump bodies, valves, pipe connectors, etc., to avoid equipment failure caused by seawater corrosion.

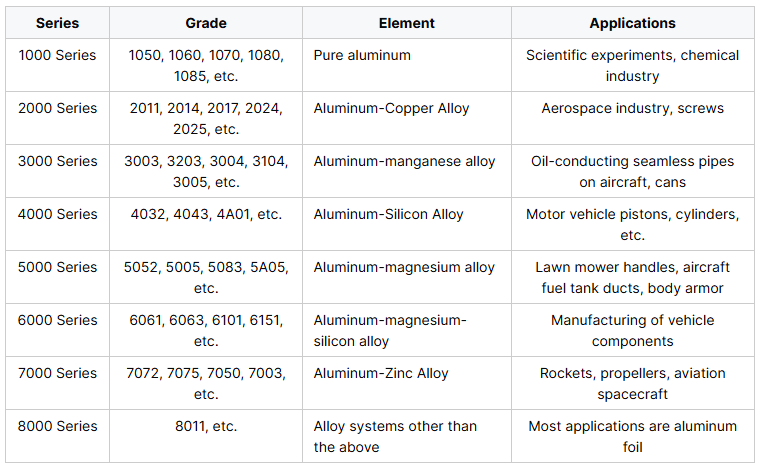

Aluminum Series