Inconel 718 vs. 625: A Buyer’s Guide to Performance, Pricing, and Sourcing

Inconel 718 vs 625: In-Depth Comparison for Selection, Pricing & Reliable Procurement

In the realm of high-performance ni-based superalloys for B2B industrial applications, Inconel 718 and Inconel 625 stand as the industry workhorses, powering critical operations in aerospace, marine engineering, chemical processing and oil & gas sectors. For procurement managers and mechanical engineers, the challenge extends far beyond understanding technical specifications—it’s about partnering with a trusted Inconel supplier that delivers premium quality at competitive prices.

At Voyage Metal, we bridge the gap between high-end material demand and cost control, specializing in genuine Inconel 718 and 625 with tailored processing solutions. This comprehensive guide breaks down the key differences between these two iconic alloys, explains the drivers behind Inconel 718 price and Inconel 625 pricing fluctuations, and reveals how our custom cutting services can significantly reduce your total project costs.

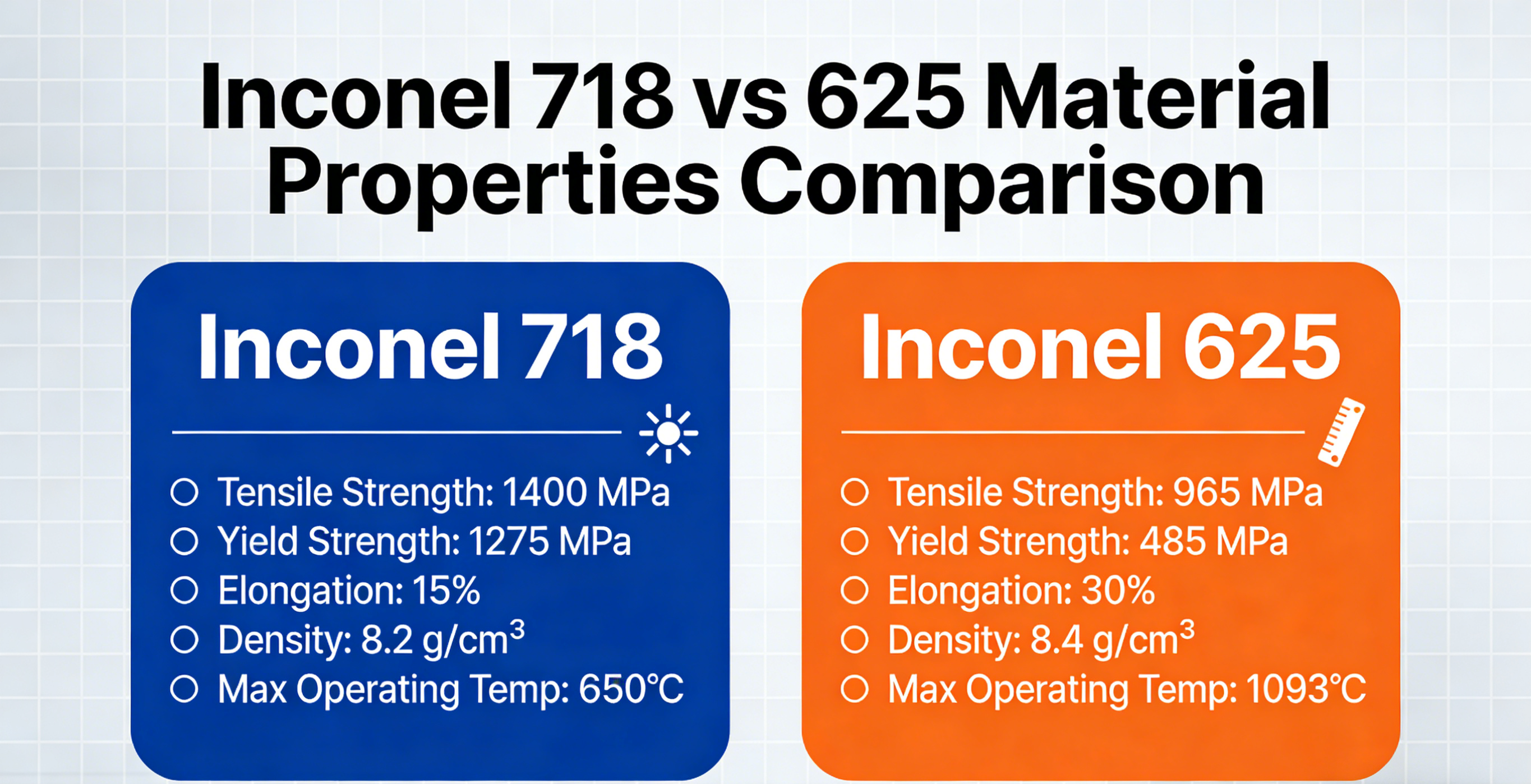

1. Core Technical Properties: Strength vs. Corrosion Resistance

Before evaluating Inconel pricing, it’s critical to ensure you’re paying for the exact performance your application requires—avoid overpaying for unneeded properties or risking equipment failure from misselection. The fundamental difference between Inconel 718 and 625 lies in their strengthening mechanisms, which define their unique performance profiles.

1.1 Inconel 718: The Precipitation Hardening Strength Expert

Core Mechanism: Precipitation (age) hardening, which forms fine strengthening phases within the alloy matrix through a precise, multi-stage heat treatment process.

Key Performance: Retains exceptional yield strength, tensile strength and creep rupture resistance at temperatures up to 700°C (1300°F), with a room temperature yield strength of 1034 MPa. It also offers excellent fatigue and stress corrosion cracking resistance in high-stress environments.

Typical Applications: Aerospace turbine blades, gas turbine components, high-strength industrial fasteners, oil drilling high-pressure structural parts, and rocket engine components.

Selection Tip: Choose Inconel 718 if your components face extreme mechanical stress and high temperatures—this alloy is the optimal investment for high-performance structural applications.

1.2 Inconel 625: The Solution Strengthened Corrosion Champion

Core Mechanism: Solution strengthening, with no age-hardening phases. Its performance is driven by a high alloy content of molybdenum and niobium, which form a robust passive film on the surface.

Key Performance: Delivers unmatched corrosion resistance—impervious to pitting, crevice corrosion, intergranular corrosion and chloride-induced stress corrosion cracking. It also offers good high-temperature oxidation resistance, with a room temperature yield strength of 414 MPa for balanced mechanical performance.

Typical Applications: Marine engineering piping systems, desalination equipment, chemical processing reactors, acidic oil & gas production equipment, nuclear power cooling systems and offshore platform components.

Selection Tip: Inconel 625 is the gold standard for corrosive environments—ideal for projects in marine, chemical and oil & gas sectors where corrosion protection is the top priority.

2. Why Do Inconel 718 and 625 Prices Fluctuate? 3 Core Drivers

When requesting quotes for Inconel 718 or 625, you’ll notice pricing is never fixed—variations exist across suppliers, product forms, delivery states and market conditions. As an experienced Inconel supplier with global supply chain expertise, we’ve identified the three non-negotiable factors that determine Inconel alloy pricing, helping you make informed procurement decisions.

2.1 Raw Material Market: LME Nickel Price is the Primary Indicator

Both Inconel 718 and 625 contain more than 50% nickel, making the LME (London Metal Exchange) nickel price the single biggest driver of their base material costs. Any spike in global nickel prices directly and immediately increases Inconel production costs.

Additionally, both alloys include high-value rare elements (niobium and molybdenum), whose market price fluctuations further impact final pricing. Inconel 625 has a higher content of molybdenum and niobium, making it more sensitive to raw material price changes than 718.

2.2 Manufacturing Complexity: Heat Treatment Drives Processing Premiums

Different strengthening mechanisms result in vastly different manufacturing processes, with direct impacts on processing costs:

- Inconel 718 requires a complex, multi-step age hardening heat treatment to achieve its peak strength—adding extra production time, labor and technical expertise that increases costs.

- Inconel 625 features a simpler heat treatment process (solution annealing), but its complex alloy composition demands higher precision in melting and casting, driving up raw melting costs.

Delivery state also affects unit pricing: Age-hardened Inconel 718, for example, commands a higher price than solution-annealed 718 due to the additional heat treatment steps.

2.3 Product Form & Custom Specifications: Higher Customization = Higher Premium

Inconel 718 and 625 are available in various forms—round bars, plates, forgings, pipes and tubes—each with different processing complexities and price points. Forgings and custom shaped parts carry a significant premium due to their high melting and forging technical barriers, compared to standard bars and plates.

For the same product form, custom specifications cost more than standard sizes. Non-standard small plates, custom-length bars and precision-cut components require secondary processing of standard raw materials, with processing waste and labor costs reflected in the final quote.

3. How to Choose a Reliable Chinese Inconel Supplier for B2B Procurement

As a high-end industrial material, genuine Inconel 718 and 625 are critical to equipment safety and performance—and the market is filled with unqualified suppliers offering substandard products. For international B2B buyers, selecting a trusted Chinese Inconel supplier requires rigorous due diligence. Verify these three key points to ensure you receive authentic, high-quality materials that meet global standards.

3.1 Verify a Genuine MTC (Material Test Certificate) to EN 10204 3.1

A professional Inconel supplier must provide a Material Test Certificate compliant with EN 10204 3.1—the global gold standard for material quality documentation. This certificate must include detailed chemical composition analysis, mechanical property test results, heat treatment parameters and batch numbers for full traceability.

The MTC is the primary document to verify material authenticity and quality, eliminating the risk of counterfeit or substandard Inconel at the source.

3.2 Confirm Compliance with International ASTM Standards

Authentic Inconel 718 and 625 must adhere to globally recognized ASTM standards to ensure compatibility with international industrial applications:

- Inconel 718: Compliant with ASTM B637 (the official standard for nickel-chromium-iron alloy bars, forgings and extrusions)

- Inconel 625: Compliant with ASTM B443 (sheets, plates and strips) and ASTM B446 (bars, forgings and extrusions)

For aerospace, nuclear power and other high-end applications, verify the supplier holds AS9100 (aerospace quality management) certification for additional quality assurance.

3.3 Evaluate Value-Added Processing Capabilities

A top-tier Inconel supplier is more than a "material shipper"—they are a one-stop procurement solution partner. Prioritize suppliers with in-house custom precision cutting, near-net shape machining, bending and forging capabilities, and the ability to process materials to your exact drawing specifications.

Suppliers with value-added processing capabilities eliminate the need for secondary downstream processing, reducing your labor, tooling and transportation costs while boosting overall procurement efficiency.

4. How Voyage Metal Optimizes Your Inconel Procurement Budget

Most buyers focus solely on the per kg/lb unit price of Inconel—yet the hidden costs of material waste, downstream machining time and tool wear often make up the largest portion of total project costs. At Voyage Metal, we address these hidden costs head-on with our tailored processing services, delivering genuine Inconel 718 and 625 at a true total cost of ownership advantage.

4.1 Custom Precision Cutting: Pay Only for What You Use

Inconel alloys are high-investment materials—and purchasing standard full-size plates (e.g., 2000mm x 6000mm) or bars for custom-sized components means you’re paying for expensive scrap. Our solution: on-demand custom cutting for Inconel 718 and 625, processing plates, bars and tubes to your exact length, size and shape per your technical drawings.

Result: You pay only for the material you actually use, with no waste costs. Additionally, reduced scrap volume cuts your international shipping costs significantly—eliminating the need to ship and store unused material.

4.2 Near-Net Shape Delivery: Reduce Machining Time & Tool Wear

Inconel is a notoriously difficult-to-machine alloy—standard raw materials require extensive cutting, milling and drilling, which is time-consuming and causes severe tool wear (a major ongoing cost). Our near-net shape delivery service processes your Inconel material to dimensions close to the final part size before shipment.

Result: Your workshop skips rough machining and moves directly to finish processing, slashing production lead times and drastically reducing tool wear. This single benefit delivers substantial cost savings for all Inconel machining projects.

5. Inconel 718 vs 625: Key Properties Comparison Table

| Key Property | Inconel 718 | Inconel 625 |

|---|---|---|

| Strengthening Mechanism | Precipitation (Age) Hardening | Solution Strengthening |

| Room Temp Yield Strength | 1034 MPa | 414 MPa |

| Core Strength | High temp strength, creep & fatigue resistance | Unmatched corrosion & chloride cracking resistance |

| Corrosion Resistance | Excellent | Exceptional (Industry Leading) |

| Machinability | Challenging (High hardness = high tool wear) | Moderate (Balanced properties = easier machining) |

| Pricing Level | High (Driven by heat treatment costs) | High (Driven by Mo/Nb raw material costs) |

| Typical Applications | Aerospace, gas turbines, high-strength fasteners | Marine engineering, chemical processing, desalination |

| Optimal Procurement Strategy | Custom cutting to reduce downstream tool wear | Custom sizing to eliminate material waste |

6. Conclusion: Partner with the Right Inconel Supplier for True Value

Whether you’re sourcing Inconel 718 for aerospace contracts or Inconel 625 for marine engineering projects, choosing the right strategic supplier is the single most important step to control costs, ensure quality and meet your project deadlines.

At Voyage Metal, we combine a stable global supply chain of genuine ASTM/EN-compliant Inconel 718 and 625 with tailored value-added processing—custom cutting, near-net shape machining and precision finishing—to optimize your total procurement costs. We are not just an Inconel supplier; we are your trusted ni-based superalloy procurement solution partner for global B2B projects.

Get Your Competitive Custom Inconel Quote Today

Send us your material specifications, technical drawings or project requirements, and our professional engineering team will create a tailored procurement solution for you— including a comprehensive quote with our custom cutting and processing services. We deliver genuine Inconel 718 and 625 that meets global standards, at a total cost of ownership that drives your project success.

Contact us now for your exclusive Inconel quote:

About Voyage Metal

Voyage Metal is a leading B2B supplier of high-performance ni-based superalloys, including Inconel 718, Inconel 625, Hastelloy and Monel. With a focus on quality, reliability and cost optimization, we serve global customers in aerospace, marine engineering, chemical processing, oil & gas and nuclear power sectors. Our core strengths include genuine material supply, custom precision processing, near-net shape delivery and one-stop procurement solutions— all designed to help our partners reduce total project costs and boost operational efficiency.