Low-Carbon Molybdenum Stainless Steel for Corrosion-Resistant, Welded, and Marine Applications

Low-carbon molybdenum austenitic stainless steel offering excellent corrosion resistance, weldability, and strength for industrial and marine environments.

Request a QuoteStainless Steel 316L (UNS S31603) is a molybdenum-containing austenitic stainless steel developed to improve resistance to pitting and crevice corrosion, especially in chloride-rich environments. The low carbon content helps minimize intergranular corrosion after welding, making 316L a preferred choice for welded structures and critical process equipment.

This grade performs well in aggressive chemical environments, seawater exposure, and low-temperature service, while maintaining good formability and fabrication characteristics.

| Standard | Designation |

|---|---|

| UNS | S31603 |

| EN / DIN | 1.4404 / 1.4435 |

| JIS | SUS 316L |

| ASTM / ASME | ASTM A240 / ASME SA240 |

| Element | Content (%) |

|---|---|

| Carbon (C) | ≤ 0.035 |

| Manganese (Mn) | ≤ 2.00 |

| Silicon (Si) | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.030 |

| Chromium (Cr) | 16.0 – 18.0 |

| Molybdenum (Mo) | 2.0 – 3.0 |

| Nickel (Ni) | 10.0 – 14.0 |

| Iron (Fe) | Balance |

| Property | Value |

|---|---|

| Tensile Strength | ≥ 515 MPa (75,000 psi) |

| Yield Strength (0.2%) | ≥ 205 MPa (30,000 psi) |

| Elongation | ≥ 35% |

| Density | 8.0 g/cm³ |

| Melting Point | ~1399 °C |

| Item | Range |

|---|---|

| Thickness | 0.1 – 100 mm |

| Width | 10 – 2500 mm |

| Length | 2000 mm / 2440 mm / 3000 mm / Custom |

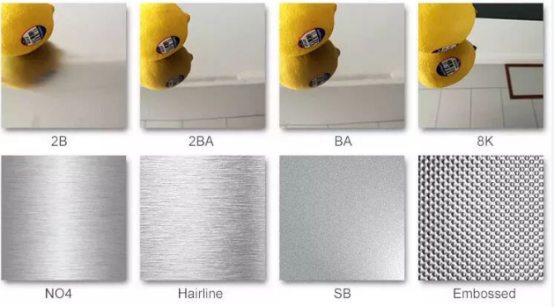

| Finish | No.1, 2B, 2D, BA, No.4, Hairline, Mirror (8K) |

| Form | Sheet, Plate, Coil, Strip, Shim, Checker Plate |

| Oil & Gas | Chemical Industry | Marine & Offshore | Food Processing | Water Treatment |

| Power Plants | Paper & Pulp | Pharmaceutical | Fabrication | Structural Systems |

| Cutting | Laser, plasma, waterjet, shearing |

| Forming | Cold forming, rolling, bending |

| Welding | TIG, MIG, resistance welding |

| Heat Treatment | Annealed / solution annealed |

Products can be supplied with comprehensive testing and inspection, including mechanical testing, hardness testing, PMI, ultrasonic testing, and corrosion-related examinations as required.

Yes. The low carbon content helps reduce the risk of intergranular corrosion after welding.

Yes. The molybdenum addition improves resistance to pitting and crevice corrosion in seawater conditions.

Yes. 316L maintains good toughness and strength at sub-zero temperatures.