Aluminum pipe is a type of non-ferrous metal pipe. It refers to a metal tubular material that is extruded from pure aluminum or aluminum alloy and is hollow along its entire longitudinal length.

Product general information

Product Name: |

2011 Aluminum Pipe |

Thickness: |

0.5mm-150mm or as the customer’s request |

OD: |

2mm-2500mm or as the customer’s request |

Length: |

3000mm, or custom made |

Service: |

Cutting, Anodizing, Custom-made. |

Technique: |

Cold Drawn, extruded |

Package: |

Export wooden pallets/cases |

Origin: |

Shanghai, China |

Commercial terms of products

Minimum Order Quantity: |

1 Ton |

Delivery Time: |

7-30 days |

Payment Terms: |

50% TT deposit, balance before shipment |

Supply Ability: |

Sea Transport, Land Transport, etc |

Other names:2011 Aluminum Alloy Tube

Description:

Aluminum pipe is a type of non-ferrous metal pipe. It refers to a metal tubular material that is extruded from pure aluminum or aluminum alloy and is hollow along its entire longitudinal length. There are seamless aluminum tubes and ordinary extruded tubes. It has the characteristics of light weight, corrosion resistance and high strength. Widely used in construction, automobile manufacturing, aerospace, electronic appliances and other fields.

OD (A) X Wall (B) X ID (C) X Length

* Dimensions in Inches

Competitive Advantage:

Excellent cutting and machining performance: this is its most core advantage. The surface finish after machining is very high, which can directly meet the surface requirements of precision parts, greatly improving the machining efficiency and qualified rate of finished products, especially suitable for batch cutting of complex shaped parts.

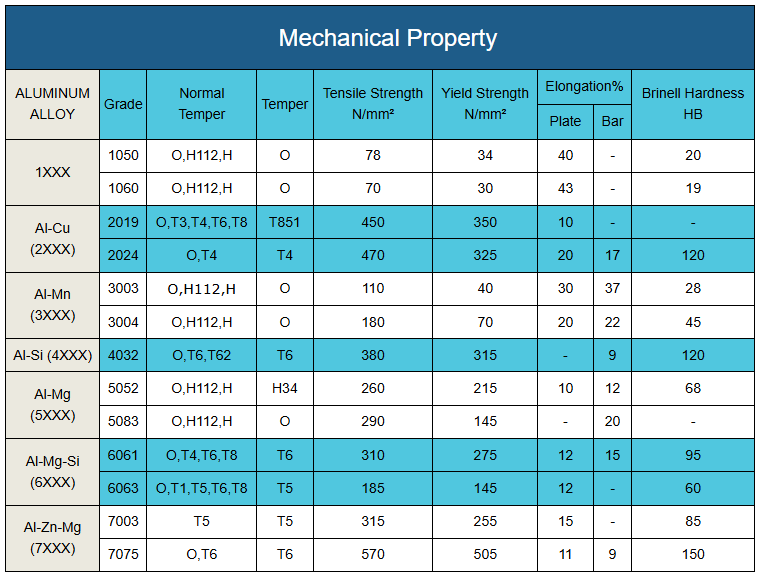

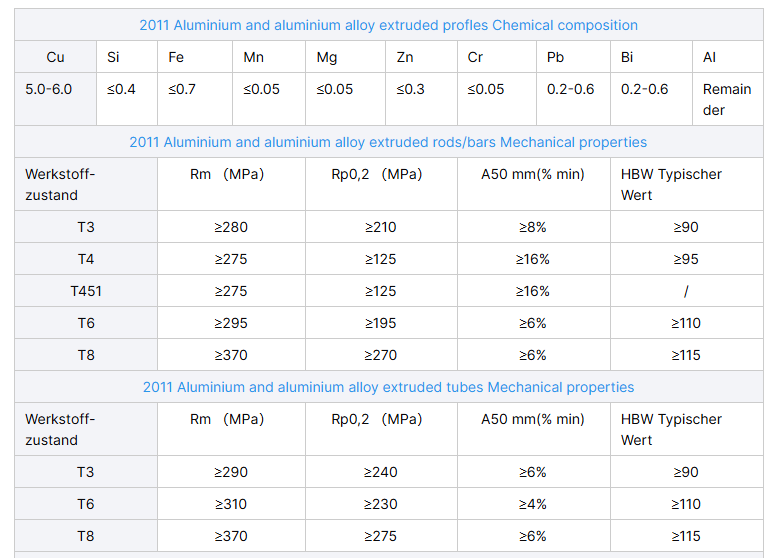

High mechanical properties: after heat treatment (such as T3, T8 state), its tensile strength can reach 380-420MPa, yield strength of about 275MPa, with good load-bearing capacity to meet the use of medium load structural components, while the hardness of moderate, and a certain degree of abrasion resistance, which reduces the wear and tear of the parts in the friction environment.

Good formability and heat treatment response: it has a certain degree of plasticity in the annealed state, and can be bent, stamped, and other simple forming processes; through solution treatment and artificial aging, it can quickly realize the strength enhancement, and it is easy to adjust the material performance according to the actual demand, and adapt to the use of different working conditions.

Balance of cost and performance: Compared with some high-strength aluminum alloys, 2011 aluminum alloy has more advantages in material cost and processing cost while guaranteeing cutting performance and medium strength, which is especially suitable for mass production scenarios with high requirements for precision machining and cost control.

Applications:

2011 Aluminum alloys show unique value in a variety of areas due to their excellent cutting properties and moderate strength. In precision instrument manufacturing, it is an ideal material for parts such as instrument gears, precision bolts, valve cores, etc. These parts often require complex cutting and stringent dimensional accuracy, and the alloy's easy chip breakage and high surface finish can efficiently meet the requirements of precision manufacturing. In the automotive industry, 2011 aluminum alloy is commonly used in the production of carburetor components, fuel system connectors and other precision parts. Its good wear resistance and machining accuracy can guarantee the stable operation of these parts under complex working conditions, while its moderate strength can also withstand the vibration and pressure around the engine.

Aluminum Series