mirror stainless steel plate

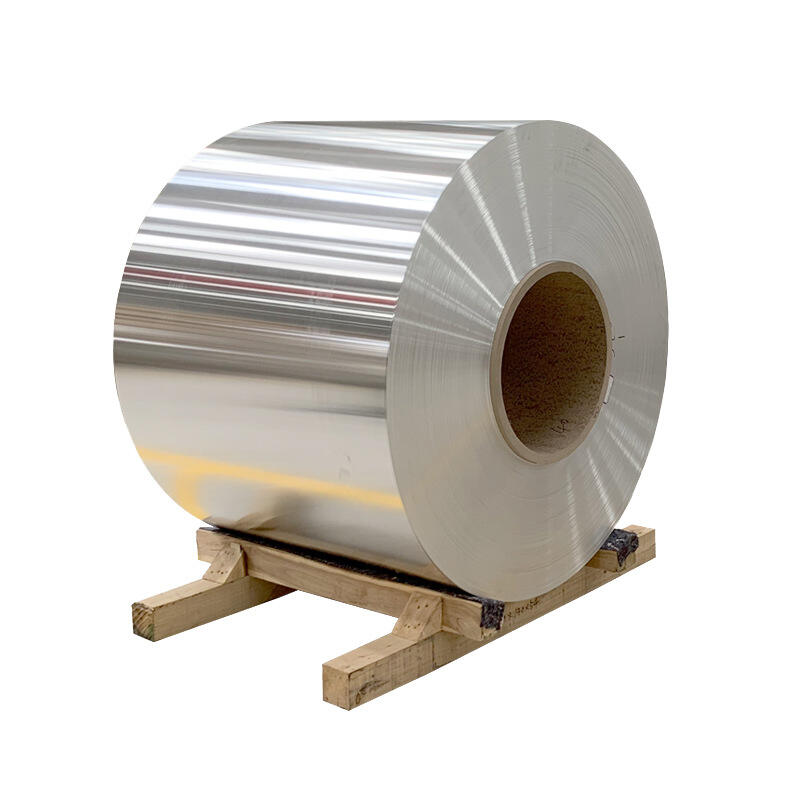

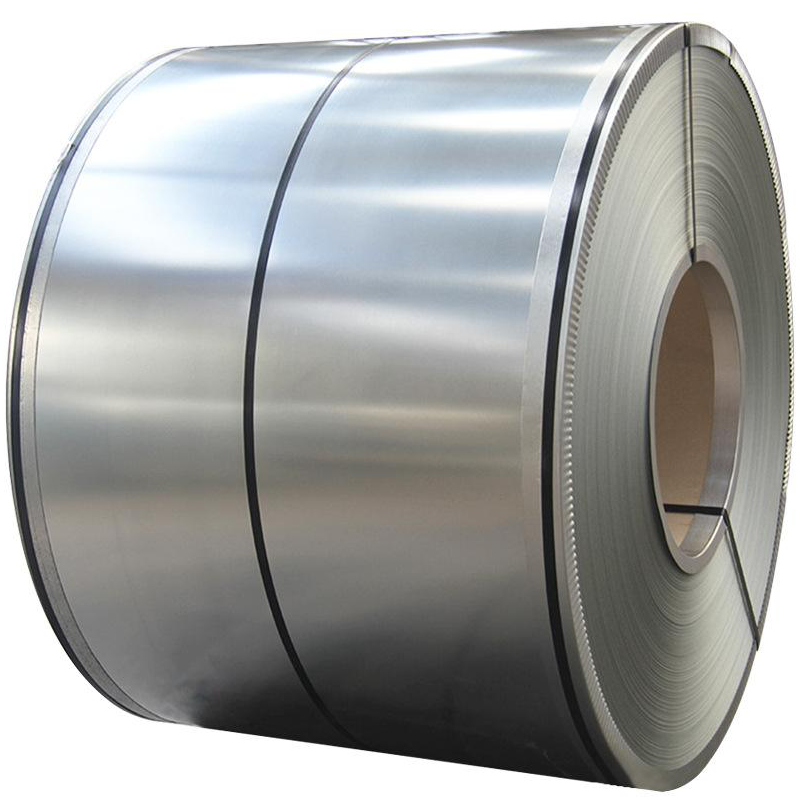

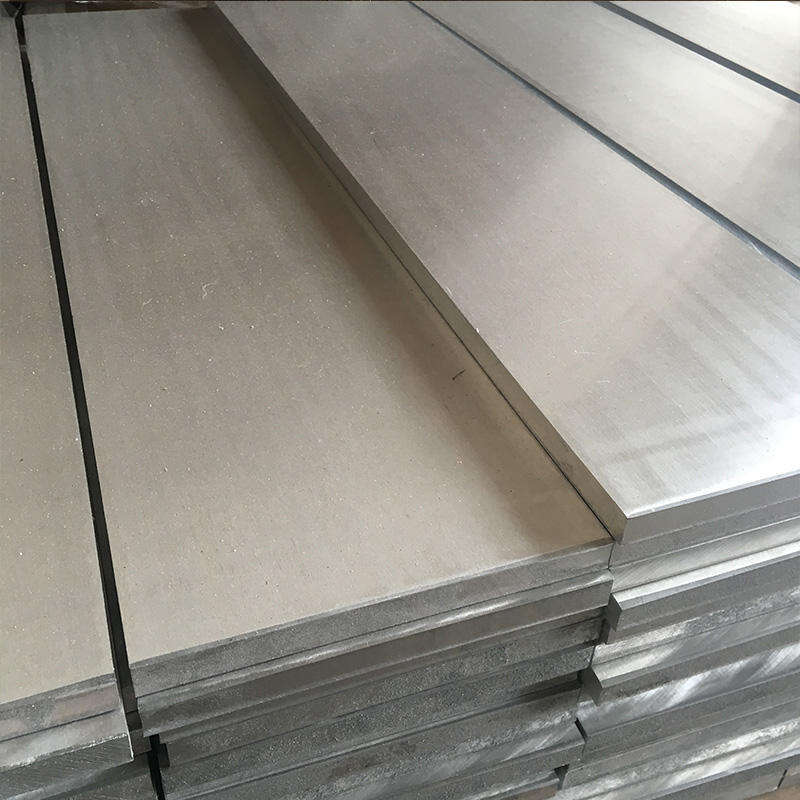

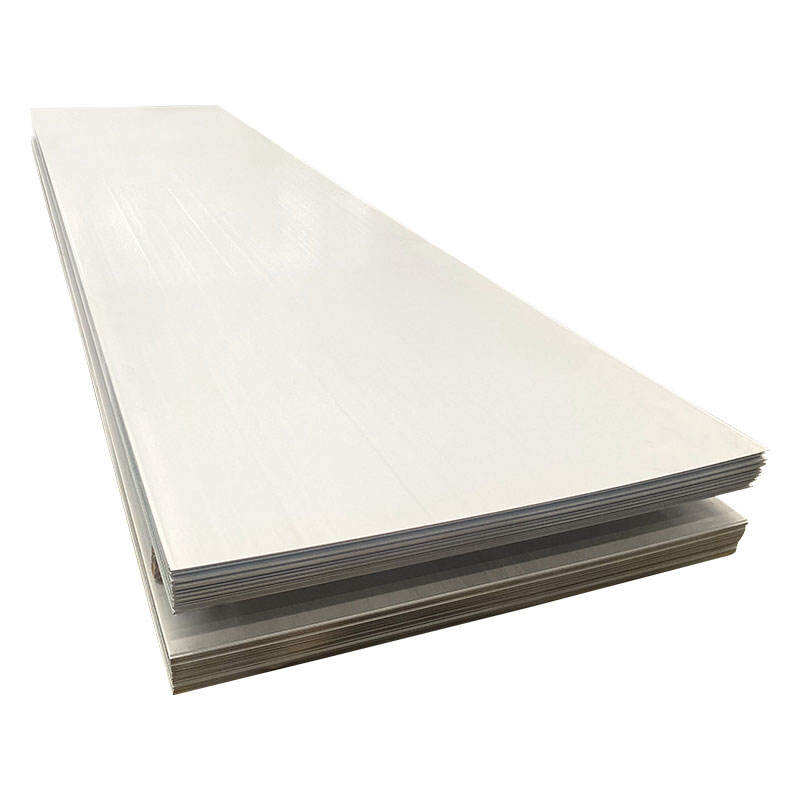

Mirror stainless steel plate represents a premium metallurgical product characterized by its highly polished, reflective surface and exceptional durability. This specialized material undergoes an intensive manufacturing process that includes precise rolling, annealing, and surface finishing techniques to achieve its distinctive mirror-like appearance. The plate typically features a surface roughness of Ra ≤ 0.2μm, delivering superior reflectivity and aesthetic appeal. Available in various grades, including 304, 316, and 430, mirror stainless steel plates combine corrosion resistance with remarkable mechanical properties. The manufacturing process involves multiple stages of polishing, utilizing progressively finer abrasives to achieve the desired mirror finish. These plates find extensive applications across diverse industries, from architectural facades and elevator interiors to high-end retail displays and medical equipment. The material's non-porous surface makes it particularly suitable for environments requiring strict hygiene standards, while its resistance to temperature fluctuations and chemical exposure ensures long-term performance reliability. Modern production techniques enable customization in terms of thickness, dimensions, and surface patterns, meeting specific project requirements while maintaining consistent quality standards.