Stainless steel pipe is a hollow long round steel product, which can be divided into seamless pipe and welded pipe. Common materials include 201, 304, 316, etc. It has the characteristics of light weight and corrosion resistance.

Product general information

Product Name: |

2205 Stainless Steel Pipe |

Thickness: |

0.5mm-75mm or as the customer’s request |

OD: |

6mm-250mm or as the customer’s request |

Length: |

200-12000mm, or custom made |

Surface: |

Polishing,annealing,pickling,bright |

Technique: |

Cold Rolled, Hot Rolled |

Package: |

Export wooden pallets/cases |

Origin: |

Shanghai, China |

Commercial terms of products

Minimum Order Quantity: |

1 Ton |

Delivery Time: |

7-30 days |

Payment Terms: |

50% TT deposit, balance before shipment |

Supply Ability: |

Sea Transport, Land Transport, etc |

Other names:2205 Stainless SteelTube

Description:

Stainless steel pipe is a hollow long round steel product, which can be divided into seamless pipe and welded pipe. Common materials include 201, 304, 316, etc. It has the characteristics of light weight and corrosion resistance. It is mainly widely used in industrial transportation pipelines and mechanical structural components such as petroleum, chemical industry, medical treatment, food, light industry, mechanical instrumentation,etc.

Chemical composition

C:≤0.03%

Cr:21.0% - 23.0%

Ni:4.5% - 6.5%

Mo:2.5% - 3.5%

N:0.08% - 0.20%

Mn:≤2.00%

Si:≤1.00%

P:≤0.03%

S:≤0.02%

Fe:Remainder

Werkstoff-zustand |

T.S(MPa) |

Y.S(MPa) |

EL(%) |

HBW Typischer Wert |

Annealed |

700-850MPa |

460-600MPa |

≥25% |

≤290HBW |

Cold Worked |

800-900MPa |

600-700MPa |

15%-20% |

280-320HBW |

Welded |

650-750MPa |

430-500MPa |

20%-35% |

230-300HBW |

Competitive Advantage:

Excellent corrosion resistance: high chromium content ensures corrosion resistance to atmosphere, fresh water and other general environments, while the addition of molybdenum and nitrogen significantly improves its resistance to chlorides, which can effectively resist pitting corrosion, crevice corrosion and stress corrosion cracking, and its performance in seawater, brine, and chlorinated media in chemical industry is far superior to that of ordinary austenitic stainless steel, and at the same time, it has good resistance to organic acids, weak bases, and so on.

High strength and good toughness:can withstand greater loads; both excellent impact toughness, even at low temperatures is not easy to brittle fracture, to achieve a balance of high strength and high toughness, suitable for high structural strength and safety requirements of the scene.

Excellent welding performance: the heat-affected zone during welding is not easy to produce embrittlement phase, the strength of the weld is close to that of the base material, and no complex heat treatment is required to maintain stable performance after welding, simplifying the manufacturing process of large components.

Economic applicability: Compared with super duplex steel with high nickel and high molybdenum, 2205 stainless steel has relatively low alloying element content, which meets the requirements of most strong corrosive working conditions with more advantageous cost and outstanding cost performance.

Applications:

With excellent corrosion resistance, high strength and good cost performance, 2205 stainless steel is widely used in many middle and high-end corrosive working conditions. In the field of seawater treatment, it is commonly used in the pipelines, filters and heat exchangers of seawater desalination system, which can effectively resist the erosion of chlorine ions in seawater and guarantee the long-term stable operation of the system; in the oil and natural gas industry, it is suitable for the pipelines and wellhead devices for conveying sulfur-containing crude oil and natural gas, and it can resist the corrosive mediums, such as hydrogen sulfide, etc., and at the same time, it can cope with the loads under the high-pressure environment with its high strength. In the shipbuilding industry, it is used as the material for the deck and seawater cooling system components of ships, taking into account the seawater corrosion resistance and structural strength.

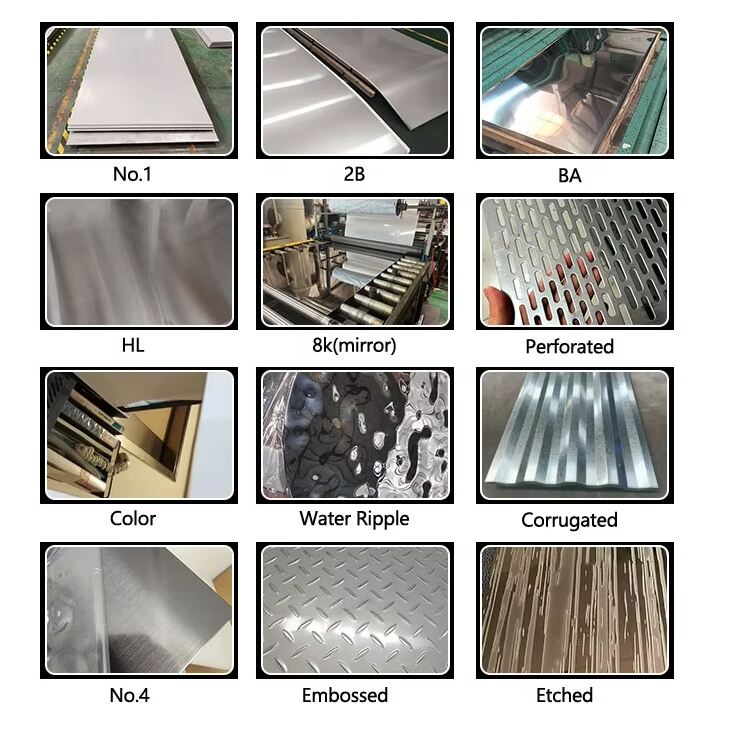

Surface

OD: |

6mm-250mm or as the customer’s request |

Length: |

200-12000mm, or custom made |

Surface: |

Polishing,annealing,pickling,bright |

Technique: |

Cold Rolled, Hot Rolled |

Package: |

Export wooden pallets/cases |

Origin: |

Shanghai, China |

Commercial terms of products

Minimum Order Quantity: |

1 Ton |

Delivery Time: |

7-30 days |

Payment Terms: |

50% TT deposit, balance before shipment |

Supply Ability: |

Sea Transport, Land Transport, etc |

Applications:

With excellent corrosion resistance and high strength, S32760 stainless steel plays an irreplaceable role in the extreme working conditions of strong corrosion and high stress, and becomes the choice of high-performance materials for extreme working conditions. In the field of marine engineering, it is the core material of seawater desalination device, which can resist the long-term erosion of high concentration of chloride ions, and is used to make reverse osmosis membrane components, seawater transport pipelines, etc. In the petrochemical industry, it is often used in the sulfur-containing crude oil refining equipment, acidic gas treatment pipelines and reactors, which can withstand the erosion of corrosive mediums, such as hydrogen sulfide, chloride, etc, and guarantee the long-term stable operation of the device. In the pulp and paper industry, it is used in the equipment parts for processing chlorine bleaching solution, which can effectively resist the loss caused by chlorine corrosion.