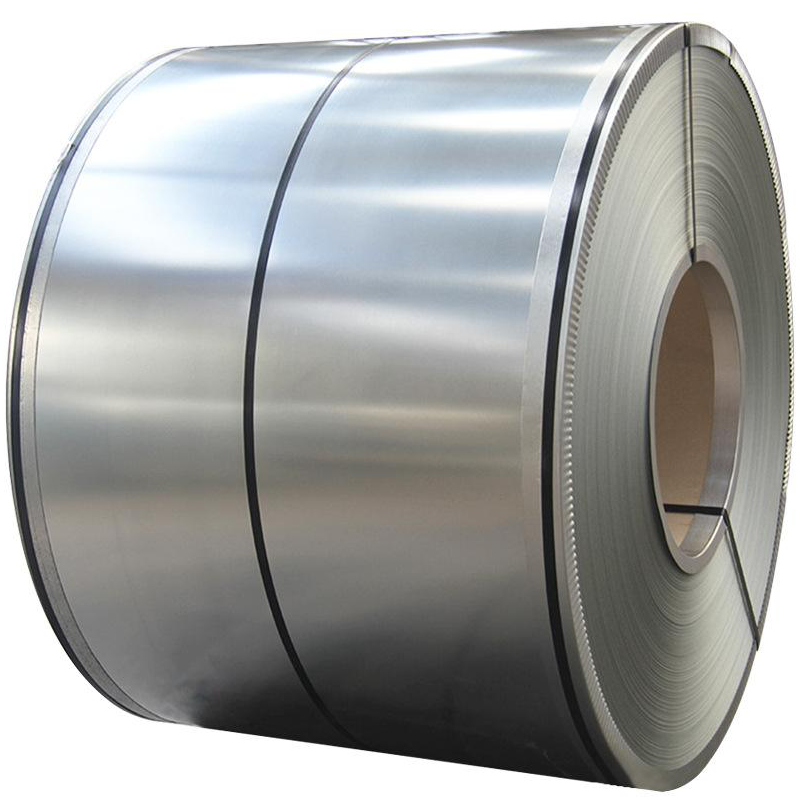

thin stainless steel plate

Thin stainless steel plate represents a versatile and essential material in modern manufacturing and construction industries. This precision engineered product combines the inherent strength of steel with the superior corrosion resistance of chromium alloy, creating a material that excels in both durability and functionality. Typically ranging from 0.3mm to 3mm in thickness, these plates are manufactured through advanced cold rolling processes that ensure consistent thickness and superior surface finish. The material composition primarily includes chromium, nickel, and other alloying elements that contribute to its remarkable resistance against various environmental factors. These plates demonstrate exceptional tensile strength while maintaining flexibility, making them ideal for applications requiring both structural integrity and malleability. In industrial settings, thin stainless steel plates find extensive use in equipment manufacturing, architectural elements, and specialized components. The material's ability to withstand extreme temperatures, chemical exposure, and mechanical stress makes it particularly valuable in food processing equipment, medical devices, and aerospace applications. Furthermore, the plates feature excellent weldability and forming characteristics, allowing for diverse fabrication methods including bending, cutting, and joining. The surface finish options range from mirror-like polish to matte textures, accommodating both functional and aesthetic requirements across different applications.