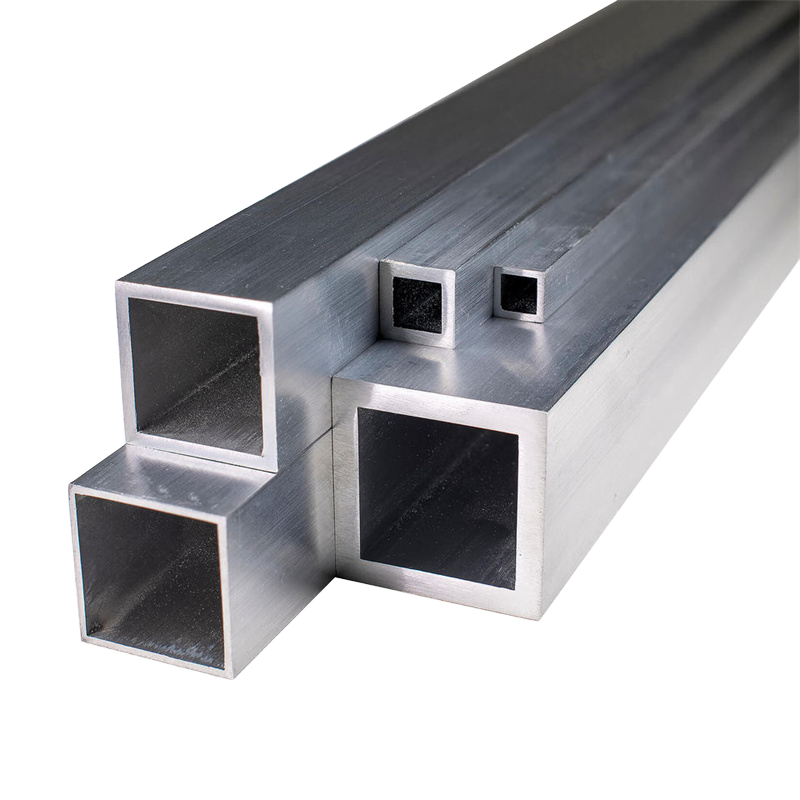

thin wall aluminum pipe

Thin wall aluminum pipe represents a significant advancement in modern industrial applications, combining lightweight properties with exceptional durability. These pipes feature precisely engineered walls that maintain structural integrity while minimizing material usage. The manufacturing process involves specialized extrusion techniques that ensure uniform wall thickness, typically ranging from 0.5mm to 2mm, while maintaining strict tolerances. These pipes excel in heat transfer applications due to aluminum's natural thermal conductivity, making them ideal for HVAC systems and heat exchangers. The corrosion-resistant properties of aluminum, enhanced by surface treatments and anodizing processes, ensure long-term reliability even in challenging environments. The pipes' smooth interior surfaces facilitate efficient fluid flow with minimal friction losses, crucial for applications in fluid transport systems. Their lightweight nature, approximately one-third the weight of steel pipes, significantly reduces installation costs and structural load requirements. The versatility of thin wall aluminum pipes extends to various industries, including aerospace, automotive, construction, and chemical processing, where they serve in applications ranging from fluid transport to structural support systems.