Aluminum pipe is a type of non-ferrous metal pipe. It refers to a metal tubular material that is extruded from pure aluminum or aluminum alloy and is hollow along its entire longitudinal length.

Product Parameter Information

Product Name: |

5052 Aluminum Pipe |

Thickness: |

0.5mm-150mm or as the customer’s request |

OD: |

2mm-2500mm or as the customer’s request |

Length: |

3000mm, or custom made |

Service: |

Cutting, Anodizing, Custom-made. |

Technique: |

Cold Drawn, extruded |

Package: |

Export wooden pallets/cases |

Origin: |

Shanghai, China |

Commercial terms of products

Minimum Order Quantity: |

1 Ton |

Delivery Time: |

7-30 days |

Payment Terms: |

50% TT deposit, balance before shipment |

Supply Ability: |

Sea Transport, Land Transport, etc |

Other names:5052 Aluminum Alloy Tube

Description:

Aluminum pipe is a type of non-ferrous metal pipe. It refers to a metal tubular material that is extruded from pure aluminum or aluminum alloy and is hollow along its entire longitudinal length. There are seamless aluminum tubes and ordinary extruded tubes. It has the characteristics of light weight, corrosion resistance and high strength. Widely used in construction, automobile manufacturing, aerospace, electronic appliances and other fields.

OD (A) X Wall (B) X ID (C) X Length

* Dimensions in Inches

Competitive Advantage:

Excellent corrosion resistance: As a non-heat-treated strengthened alloy, 5052 aluminum alloy has outstanding corrosion resistance among aluminum alloys, especially in humid environments such as fresh water and sea water, and can effectively resist electrochemical corrosion and stress corrosion.

Excellent plasticity and formability: 5052 aluminum alloy has excellent plasticity, with an elongation of more than 25%. It is easy to cold-form, such as stamping, bending, rolling, etc. It can be processed into parts with complex shapes (such as curved plates and special-shaped parts), and it is not easy to crack after forming. It is suitable for manufacturing components with complex appearance or requiring multiple deformations.

Medium strength and good weldability: It is at a higher level among non-heat-treated strengthened alloys and can meet the load-bearing requirements of general structural parts. At the same time, it has excellent welding performance and can be welded by various methods such as argon arc welding and resistance welding. The joint strength loss after welding is small, and the corrosion resistance of the weld area can still maintain a good level.

Good low temperature performance: In low temperature environment (such as -196℃), the mechanical properties of 5052 aluminum alloy will not decrease, but slightly improve, and the plasticity and toughness remain stable, which is suitable for low temperature equipment or structural parts in cold areas.

Excellent surface treatment performance: The alloy is easy to surface treat, such as anodizing to form a uniform and dense oxide film, which can not only further enhance the corrosion resistance, but also give it rich colors through dyeing, taking into account both functionality and decoration, and is often used for parts that require beautiful appearance.

Applications:

5052 aluminum alloy is widely used in many fields due to its balanced performance. In shipbuilding, its seawater corrosion resistance makes it the preferred choice for ship decks and cabin components, and its moderate strength meets the hull load-bearing requirements; in the automotive industry, its excellent plasticity is suitable for making fuel tanks and body panels, and its lightweight helps reduce fuel consumption, while its weldability ensures structural stability. In the field of architectural decoration, its easy surface treatment characteristics make curtain wall panels, blinds, etc. both corrosion-resistant and beautiful; in medical equipment, it can be used for equipment frames and shells, and its moderate strength ensures stability, and after surface treatment, it meets hygiene standards; in the manufacture of low-temperature equipment, refrigerated truck boxes, low-temperature storage tank shells, etc. rely on its stable mechanical properties at low temperatures to ensure reliable storage and transportation of materials.

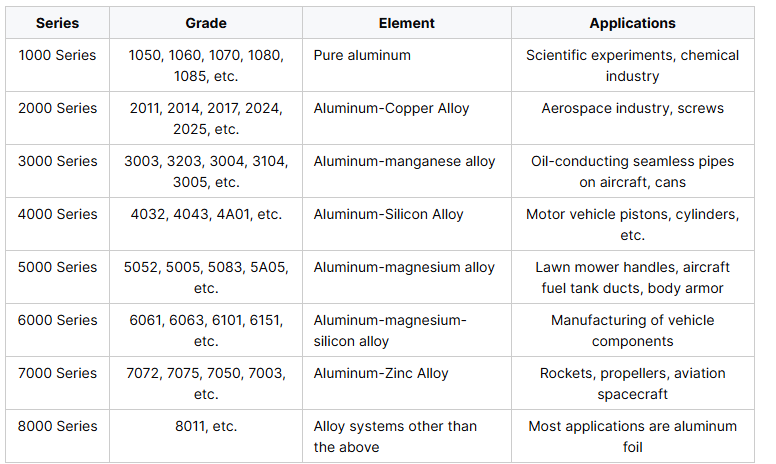

Aluminum Series