Ultra-thin walls & micro-diameter for precision flow control

Manufactured from premium nickel-based alloys with excellent corrosion & heat resistance

Support customized sizes, lengths, and surface treatments for diverse industry needs

Our nickel alloy capillary tubes are engineered for applications that require micro-diameter precision, excellent corrosion resistance, and stable performance under extreme conditions. Using high-grade nickel-based alloys including Inconel, Monel, Hastelloy, Incoloy, Nickel 200/201, and others, the tubing maintains reliable performance in high-temperature, high-pressure, and chemically aggressive environments.

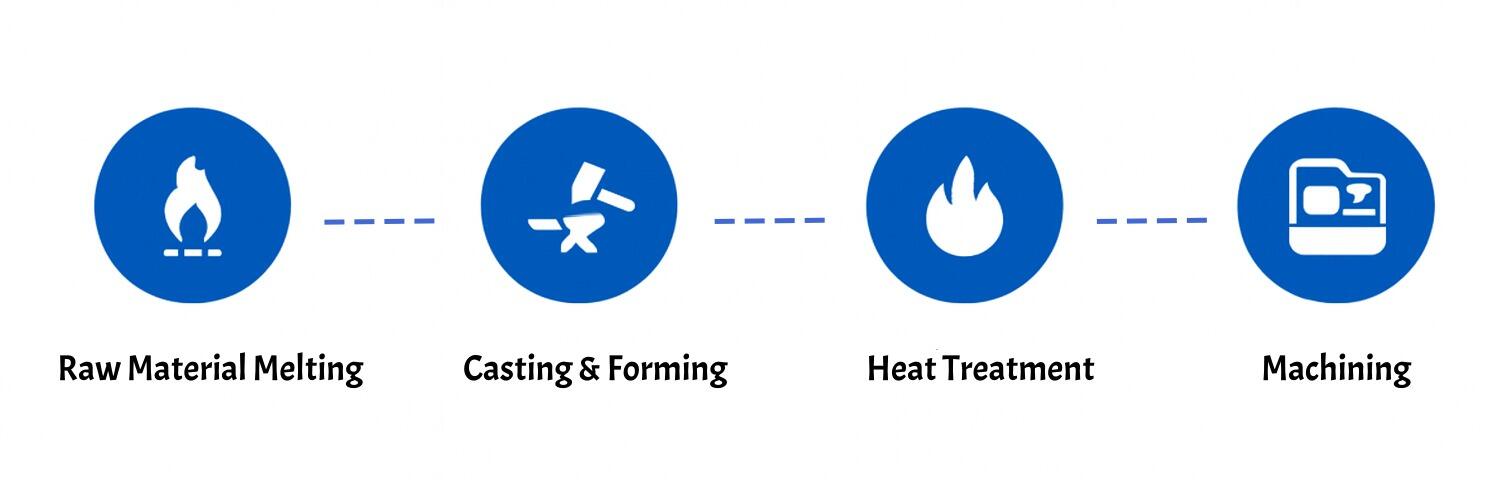

With advanced drawing, solution treatment, and annealing processes, each capillary tube features uniform wall thickness, smooth inner surfaces, superior flexibility, and high fatigue strength, ensuring stable flow control and accurate signal transmission.

We support custom manufacturing with special tolerances, long-length coils, and optional polishing or pickling surface treatments.

| Parameter | Specification Range | Notes |

|---|---|---|

| Outer Diameter | 0.1 mm – 6 mm | Micro-diameter custom precision tubes |

| Wall Thickness | 0.01 mm – 2 mm | Ultra-thin-wall options available |

| Length | Up to 30 meters continuous | Custom coil lengths available |

| Delivery Condition | Solution-treated / Annealed / Cold-worked | Meets different application requirements |

| Surface Finish | Pickled / Polished / Bright | Suitable for multiple industries |

| Alloy Category | Alloy Name | UNS | Standard |

|---|---|---|---|

| Pure Nickel | Nickel 200 | N02200 | B161/B163 |

| Pure Nickel | Nickel 201 | N02201 | B161/B163 |

| Hastelloy | C-276 | N10276 | B622 |

| Hastelloy | C-22 | N06022 | B622 |

| Hastelloy | C-2000 | N06200 | B622 |

| Hastelloy | C-4 | N06455 | B622 |

| Hastelloy | B-2 | N10665 | B622 |

| Hastelloy | B-3 | N10675 | B622 |

| Hastelloy | G-30 | N06030 | B622 |

| Hastelloy | X | N06002 | B622 |

| Inconel | 600 | N06600 | B167/B163 |

| Inconel | 601 | N06601 | B167/B163 |

| Inconel | 625 | N06625 | B444 |

| Inconel | 690 | N06690 | B167/B163 |

| Inconel | 718 | N07718 | B983 |

| Inconel | X-750 | N07750 | — |

| Monel | 400 | N04400 | B165/B163 |

| Monel | K-500 | N05500 | — |

| Incoloy | 800 | N08800 | B407/B163 |

| Incoloy | 800H | N08810 | B407/B163 |

| Incoloy | 800HT | N08811 | B407/B163 |

| Incoloy | 825 | N08825 | B423/B163 |

| Incoloy | 925 | N09925 | — |

| Incoloy | Alloy 20 | N08020 | B729 |

| Nimonic | 80A | N07080 | — |

| Nimonic | 90 | N07090 | — |

| Nimonic | Alloy 263 | N07263 | — |

| Waspaloy | Waspaloy | N07001 | — |

| Haynes | 188 | R30188 | — |

| Haynes | 25 (L-605) | R30605 | — |

| NILO Alloy | Invar 36 | K93600/K93601 | — |

| NILO Alloy | Alloy 42 | K94100 | F30 |

| NILO Alloy | Kovar | K94610 | F15 |

Imported automated production lines with advanced spectrometers & tensile testing

Precision machining capability for non-standard & ultra-tiny sizes

Fast delivery (3–5 days) on regular specifications

Technical engineering support for material selection & custom specifications

Aerospace — hydraulic micro-pipes, fuel transmission micro-tubes

Oil & Gas — downhole sensing tubes, pressure control tubing

Chemical Processing — sampling lines, corrosion-resistant micro pipelines

Marine Engineering — deep-sea detection instruments

Biopharmaceutical — sterile fluid micro-delivery systems

Medical Devices — catheters, endoscopic microtubes

Semiconductor — ultra-pure gas pipelines, lithography cooling lines

Military & Defense — micro hydraulic systems, precision instrument conduits