Test

Aerospace Engineering

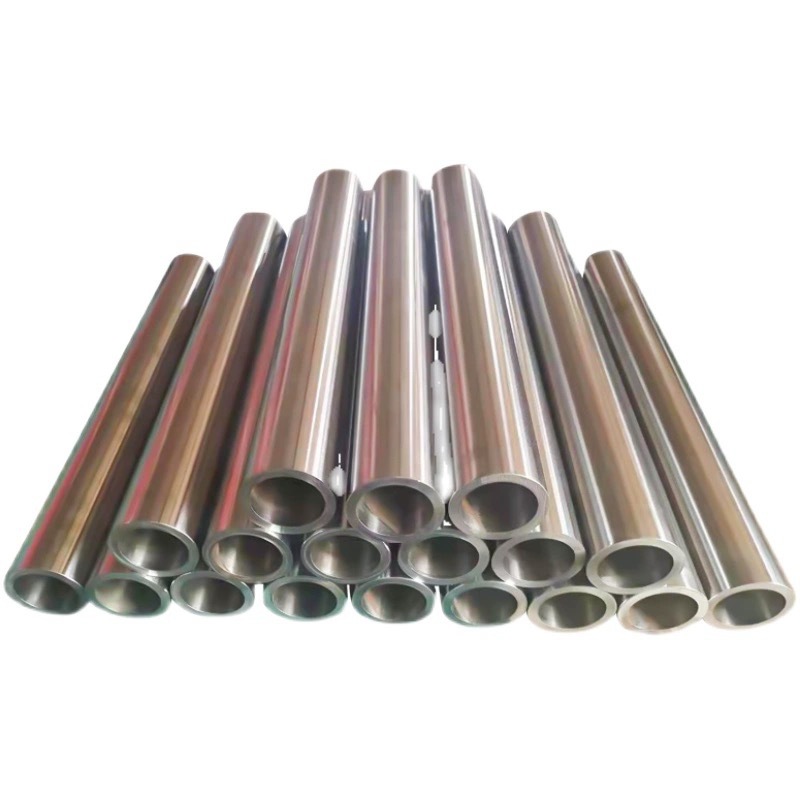

High-performance metal materials for aerospace structures and components requiring strength, precision, and extreme environmental resistance.

Detailed Description

Aerospace engineering is one of the most demanding application fields for metal materials, requiring exceptional strength-to-weight ratio, dimensional accuracy, thermal stability, and long-term reliability.

Materials used in aerospace applications must perform consistently under extreme conditions, including high temperature, pressure variation, vibration, and corrosive environments.

Titanium, nickel alloys, stainless steel, and high-performance aluminum are commonly used in aerospace manufacturing due to their proven performance in critical systems. Titanium is widely valued for its lightweight characteristics combined with high strength and corrosion resistance. Nickel alloys are essential in high-temperature zones, such as engine-related components, where thermal stability and creep resistance are required. Stainless steel and aluminum are applied in structural parts, support systems, and auxiliary components.

These materials are used in both civil and industrial aerospace projects, supporting manufacturing, maintenance, and engineering development across a wide range of aerospace systems.

Common Aerospace Materials & Applications

| Material | Typical Aerospace Use | Key Performance Advantage |

| Titanium | Structural components, fasteners | High strength, lightweight, corrosion resistance |

| Nickel Alloys | Engine & heat-resistant parts | High-temperature stability |

| Stainless Steel | Structural & support systems | Corrosion resistance, durability |

| Aluminum | Frames, housings | Lightweight, good machinability |

Typical Aerospace Applications

●Aircraft structural components

●Engine and heat-resistant systems

●Aerospace fasteners and fittings

●Support frames and housings

●Precision-machined aerospace parts

All materials used in aerospace engineering must meet strict quality control requirements, including chemical composition consistency, mechanical performance stability, and precise dimensional tolerances.

🔍 Why Material Selection Matters in Aerospace Engineering

In aerospace engineering, material selection directly affects flight safety, system reliability, and long-term operational performance.

Even minor material defects or inconsistencies can lead to structural fatigue, component failure, or reduced performance under extreme operating conditions.

Titanium is selected for its ability to maintain strength while significantly reducing overall system weight, which is critical for fuel efficiency and payload optimization. Nickel alloys are chosen for environments exposed to extreme heat, where conventional materials may deform or lose mechanical strength. Stainless steel and aluminum must offer consistent performance during vibration, pressure fluctuations, and long service cycles.

By selecting materials with appropriate mechanical properties, thermal resistance, and corrosion behavior, aerospace manufacturers and engineers can ensure structural integrity, extend component service life, and comply with strict aerospace engineering standards.

Case: Precision Metal Integration in Aerospace Subsystem Assembly

Project Context

This case involved metal materials supplied for components used within an aerospace subsystem assembly.

The engineering focus extended beyond strength, emphasizing dimensional control, consistency, and system compatibility.

In aerospace applications, even non-primary components must meet strict performance expectations due to the interconnected nature of system assemblies.

Engineering Environment

Materials underwent precision machining, inspection, and controlled assembly processes.

Small deviations in material behavior could affect alignment, tolerance stacking, or long-term system reliability.

The project required materials that behaved predictably across multiple production stages.

Material Application in the System

High-performance alloys were used in components where strength-to-weight balance was critical.

Stainless steel and aluminum were applied in support structures and auxiliary assemblies where manufacturability and dimensional stability were required.

Materials were supplied in controlled forms to support advanced machining and inspection procedures.

Engineering Outcome

The components were successfully integrated into the aerospace subsystem without material-related deviation.

From an engineering perspective, the project demonstrated that material consistency at the earliest stage is a key factor in achieving precision system integration.