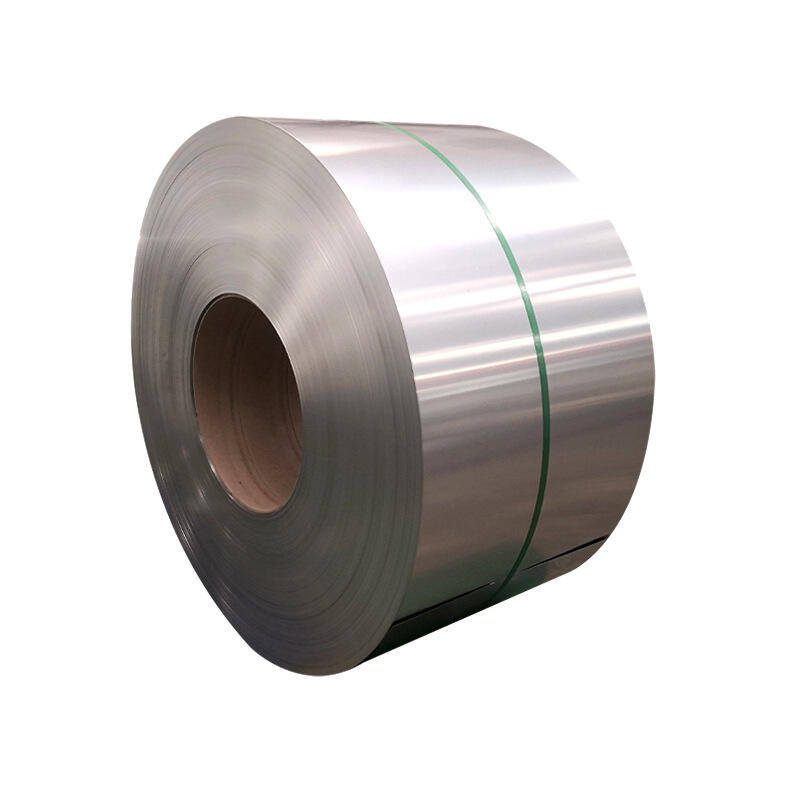

aluminum coil stock suppliers

Aluminum coil stock suppliers play a pivotal role in the global metal manufacturing industry, providing essential materials for various applications. These suppliers specialize in producing and distributing high-quality aluminum coils that serve as the foundation for numerous industrial and commercial products. The aluminum coils are manufactured through a sophisticated process that involves rolling raw aluminum into thin sheets and winding them into coils for easier transportation and handling. These suppliers maintain strict quality control measures throughout the production process, ensuring consistent material properties such as thickness, width, and surface finish. They offer various grades and tempers of aluminum coils to meet specific customer requirements, from soft and malleable varieties to harder, more durable options. Modern aluminum coil suppliers utilize advanced technology in their production facilities, including precision rolling mills, tension leveling equipment, and automated quality inspection systems. They also provide value-added services such as custom cutting, slitting, and surface treatments to enhance the material's performance characteristics. The suppliers maintain extensive inventory systems and efficient distribution networks to ensure prompt delivery and reliable supply chain management for their customers worldwide.