Aluminum coil is a metal sheet, which is melted from aluminum ingots, added with different alloys, and processed into aluminum coils through casting, hot rolling, cold rolling, annealing , cross-cutting and other processes.

Product general information

Product Name: |

5083 Aluminum Coil |

Thickness: |

0.3mm-20mm or as the customer’s request |

Width: |

60mm-2500mm or as the customer’s request |

Length: |

2000-12000mm, or custom made |

Surface: |

Polished,Mill Finished,anodized or power sprayed |

Technique: |

Cold Drawn, Hot Rolled |

Package: |

Export wooden pallets/cases |

Origin: |

Shanghai, China |

Commercial terms of products

Minimum Order Quantity: |

1 Ton |

Delivery Time: |

7-30 days |

Payment Terms: |

50% TT deposit, balance before shipment |

Supply Ability: |

Sea Transport, Land Transport, etc |

Other names:5083 Aluminum Alloy Roll

Description:

Aluminum coil is a metal sheet, which is melted from aluminum ingots, added with different alloys, and processed into aluminum coils through casting, hot rolling, cold rolling, annealing , cross-cutting and other processes. It has the characteristics of corrosion resistance, high strength , light weight , and good electrical and thermal conductivity . Widely used in construction , packaging , automobile manufacturing , electronics industry and other fields.

Werkstoff-zustand |

T.S(MPa) |

Y.S(MPa) |

EL(%) |

HBW Typischer Wert |

O |

270~350 |

125~200 |

≥12-16 |

60~75 |

H116 |

300~340 |

215~250 |

8~12 |

80~95 |

H32 |

300~340 |

215~250 |

8~12 |

80~95 |

Feature:

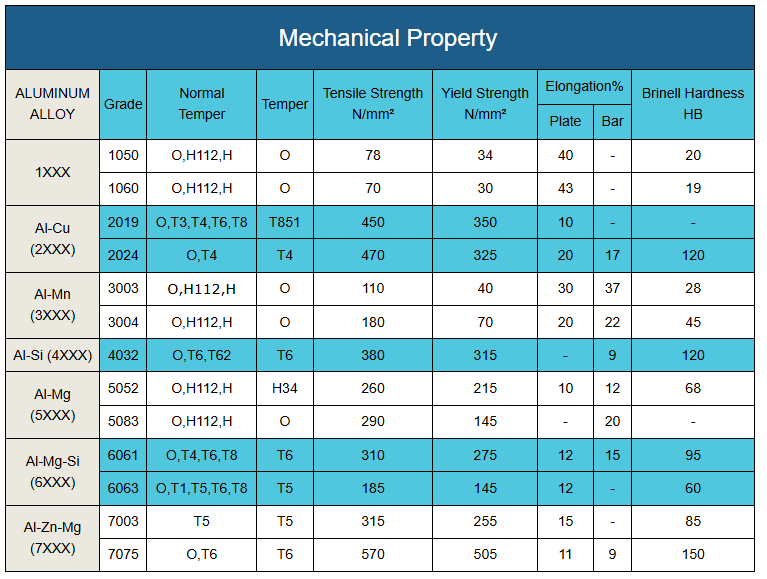

High strength and excellent mechanical properties: 5083 aluminum alloy tensile strength of up to 300-350MPa, yield strength of about 210MPa, in similar alloys belongs to the high-strength level, can withstand a large load, while having good toughness, elongation at break can reach more than 20%, impact resistance is excellent, not easy to brittle fracture.

Excellent corrosion resistance: especially outstanding in the marine environment, seawater, salt spray, etc. has a strong resistance, far better than most of the aluminum-copper alloy, which makes it without complex surface treatment can be used in the humid or corrosive environment for a long time, is the ideal material for marine engineering.

Excellent welding performance: Argon arc welding, electrode arc welding and other conventional welding processes, high strength of the weld seam and the corrosion resistance of the welded area is almost unaffected, no heat treatment after welding to maintain the integrity and stability of the structure, suitable for large-scale components of the splicing manufacturing.

Good processing and forming performance: despite the high strength, 5083 aluminum alloy still has good plasticity, can be cold rolled, hot rolled, forging and other processing, can be made into plate, bar, profile and other forms, and easy to bend, stamping into complex shapes to meet the forming needs of different structural components.

Outstanding low-temperature performance: in the ultra-low temperature environment of - 196 ℃, its mechanical properties not only do not decline, on the contrary, the toughness has been improved, and can adapt to extreme environments, such as polar, low-temperature storage, which is the preferred material for the manufacture of low-temperature equipment.

Applications:

5083 aluminum alloy plays a key role in many fields due to its high strength, excellent corrosion resistance and excellent welding performance. In the field of marine engineering, it is the core material for making structural parts of offshore platforms and seawater pipelines, which can resist long-term erosion by seawater, and at the same time, its high strength can withstand wind and wave loads in the marine environment; in shipbuilding, it is commonly used in the hulls of speedboats and the decks of yachts, etc., and it does not require complicated treatment to maintain a solid structure after welding, and its lightweight characteristics can help to increase the sailing efficiency of the ships. In the automotive industry, the alloy is used in the body frames of some off-road vehicles, taking into account the needs of impact resistance and lightweight; in addition, in the chemical industry, it can be used to make corrosion-resistant reaction kettles, pipelines, and good processing performance to meet the requirements of the manufacture of complex structures, which has become the preferred material to take into account the performance and practicality of many industries.

Aluminum Series