best stainless steel plate

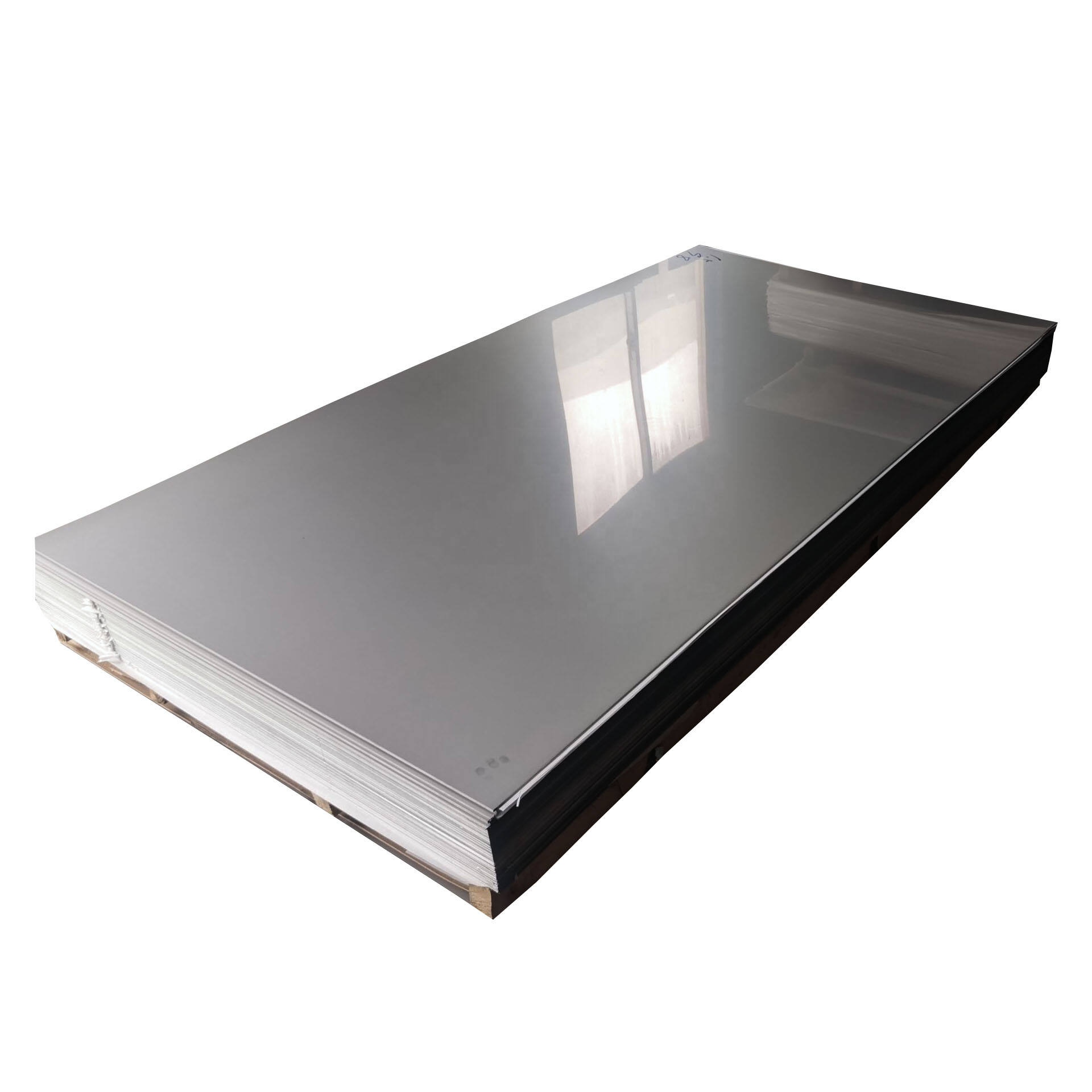

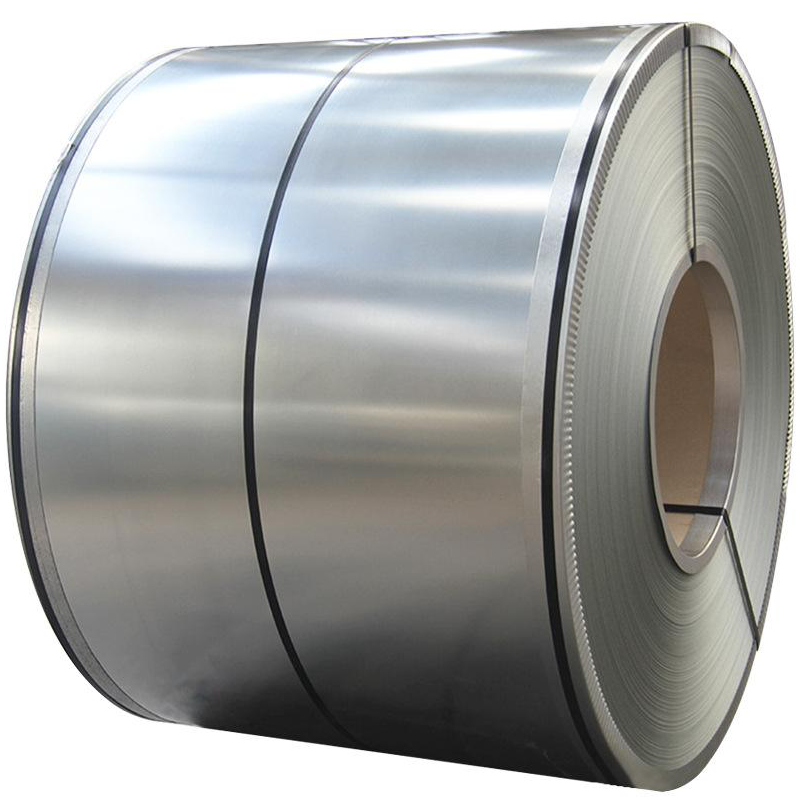

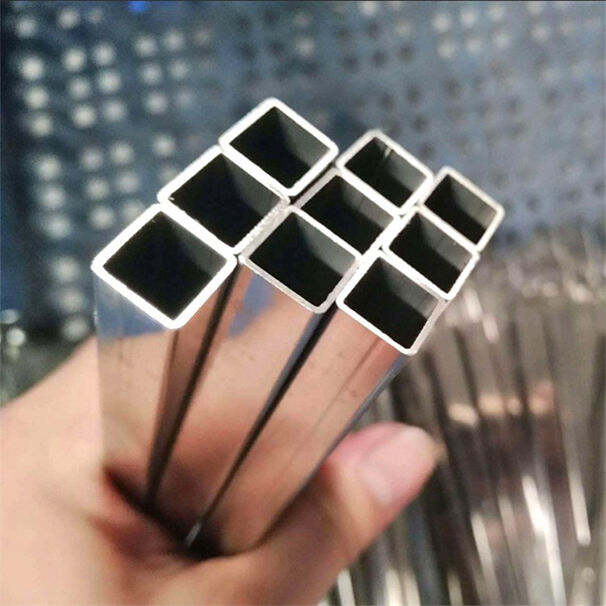

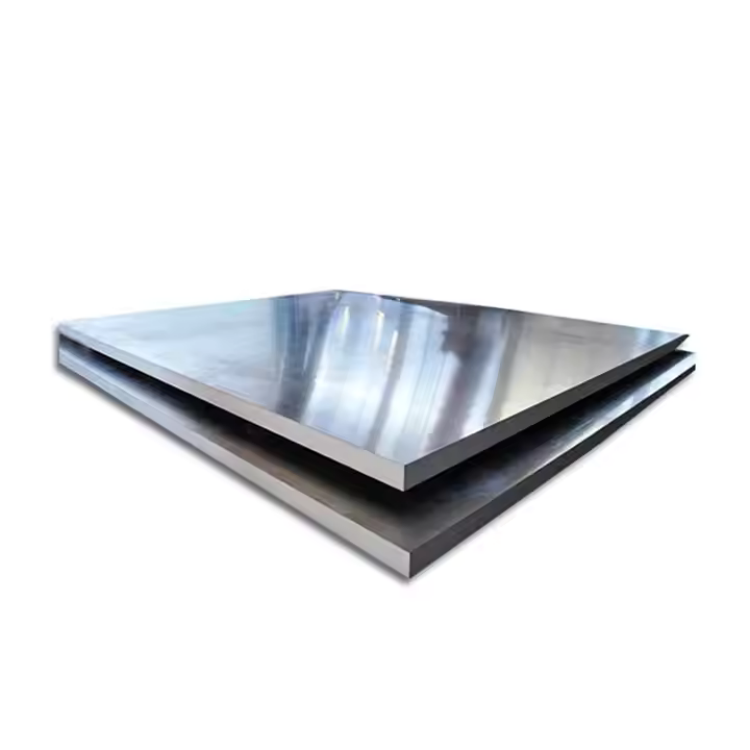

The best stainless steel plate represents the pinnacle of metallurgical engineering, combining durability, versatility, and aesthetic appeal. These premium plates are manufactured using advanced cold-rolling technology and precise temperature control processes, ensuring exceptional flatness and superior surface finish. The plates feature a carefully balanced composition of chromium, nickel, and molybdenum, creating an optimal blend that delivers outstanding corrosion resistance and mechanical properties. Available in various grades including 304, 316, and 430, these plates offer thickness ranges from 0.4mm to 50mm, making them suitable for diverse applications. The manufacturing process incorporates stringent quality control measures, including ultrasonic testing and x-ray inspection, guaranteeing structural integrity and dimensional accuracy. These plates excel in environments requiring high temperature resistance, chemical exposure tolerance, and maintain their structural integrity in extreme conditions. Their applications span across multiple industries, from food processing equipment and architectural facades to heavy industrial machinery and marine applications. The surface finish options include 2B, BA, and No.4, catering to different aesthetic and functional requirements while ensuring consistent quality across every sheet.