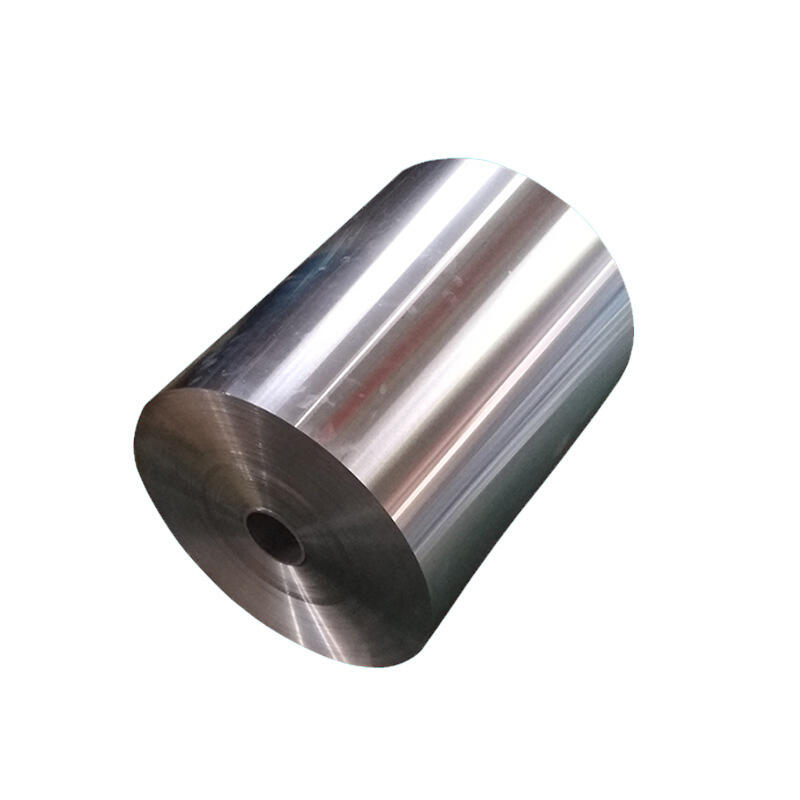

coated aluminum coil

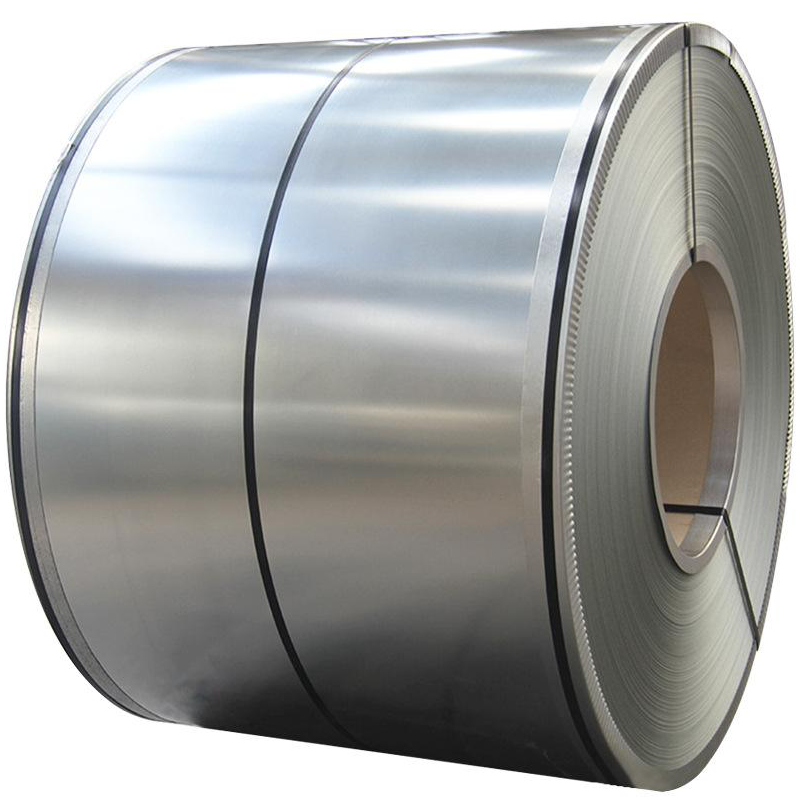

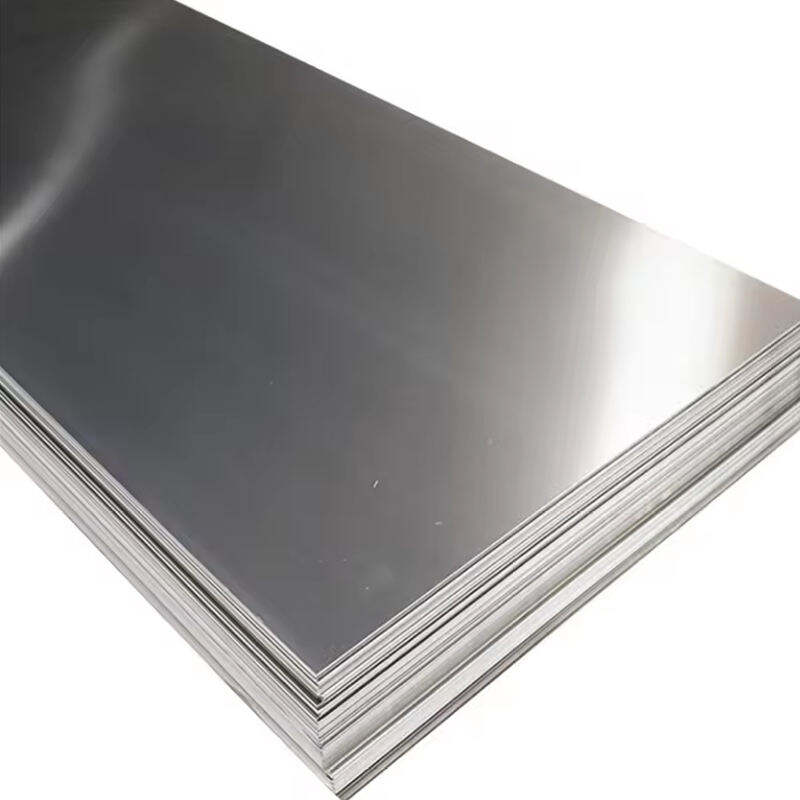

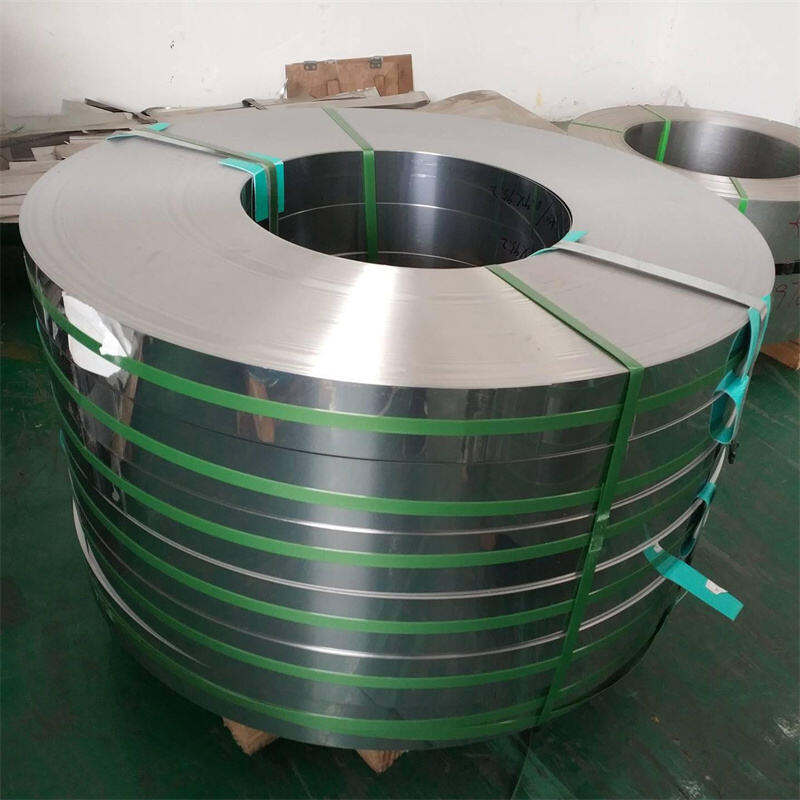

Coated aluminum coil represents a sophisticated advancement in metal processing technology, combining the inherent properties of aluminum with protective and decorative surface treatments. This versatile material consists of a high-quality aluminum core that undergoes a specialized coating process, resulting in enhanced durability and aesthetic appeal. The coating, typically applied through advanced roll-coating or spray-coating methods, creates a protective barrier that shields the aluminum substrate from environmental factors, corrosion, and wear. These coils are manufactured in various thicknesses, widths, and coating compositions to meet diverse industrial requirements. The coating process can incorporate different materials, including polyester, PVDF, epoxy, or specialized formulations, each offering specific performance characteristics. Modern coated aluminum coils feature exceptional weather resistance, superior color retention, and remarkable durability, making them ideal for both outdoor and indoor applications. The material's lightweight nature, combined with its structural integrity, provides architects and manufacturers with a cost-effective solution that doesn't compromise on quality or performance. These coils find extensive use in construction, automotive manufacturing, appliance production, and numerous other industrial applications where both functionality and appearance are crucial considerations.