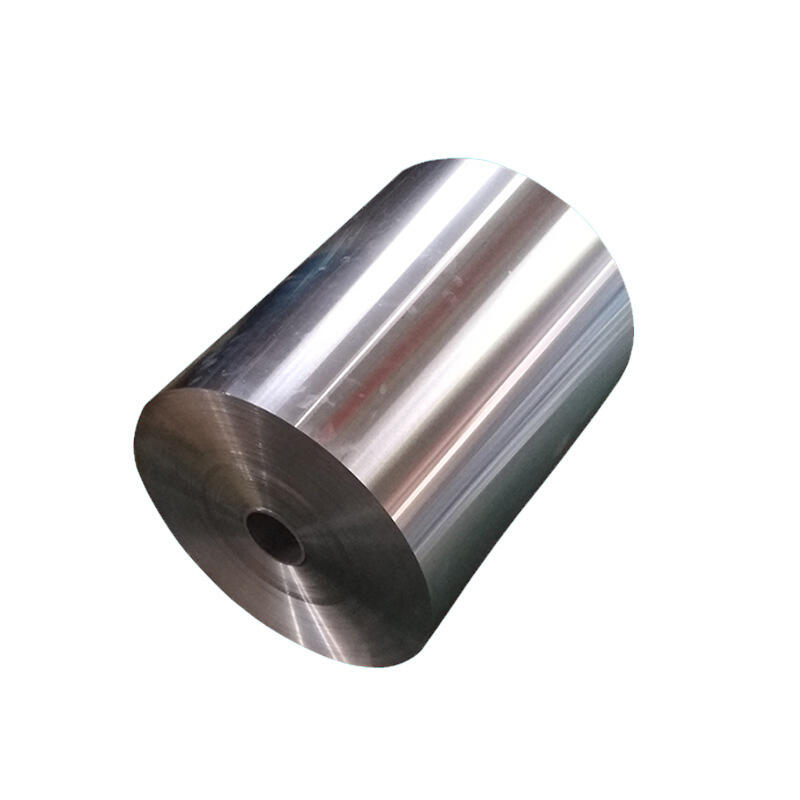

aluminum coil for sale

Aluminum coil for sale represents a versatile and essential industrial material that combines durability with exceptional versatility. These precision-manufactured coils are produced through an advanced rolling process that ensures consistent thickness and superior surface quality. Available in various grades, tempers, and dimensions, aluminum coils serve diverse applications across multiple industries. The material features outstanding corrosion resistance, excellent thermal conductivity, and remarkable strength-to-weight ratio, making it an ideal choice for both structural and aesthetic applications. The manufacturing process incorporates state-of-the-art quality control measures, ensuring each coil meets rigorous industry standards. These coils can be customized with different surface treatments, including mill finish, embossed, or pre-painted options, catering to specific project requirements. The material's inherent properties make it particularly suitable for construction, automotive, packaging, and architectural applications. Modern production techniques enable precise thickness control and superior flatness, crucial for downstream processing. Furthermore, these aluminum coils are engineered to maintain their structural integrity during forming and fabrication processes, ensuring optimal performance in final applications.