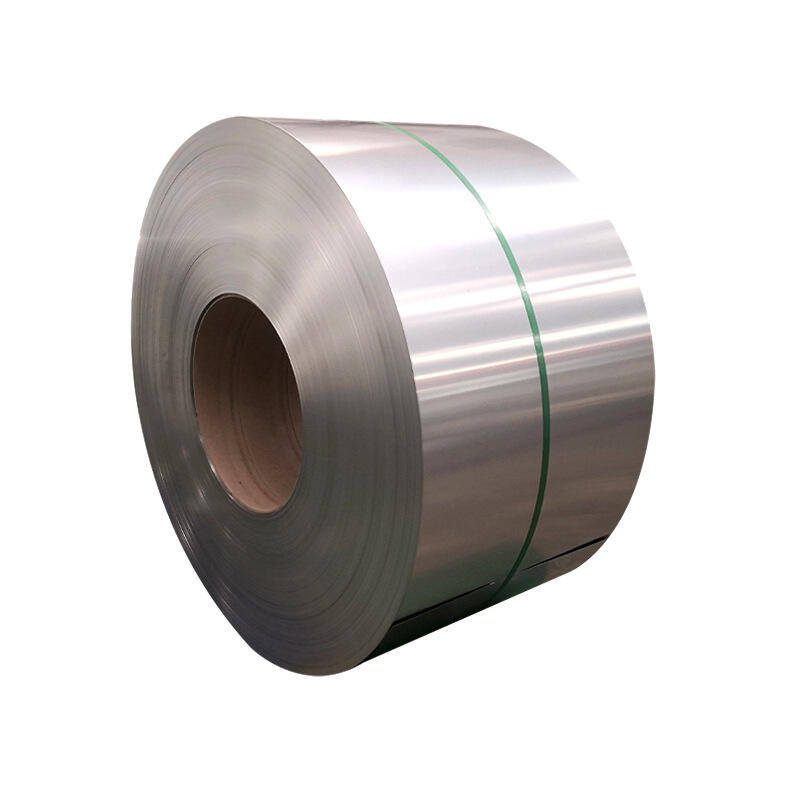

aluminum coil sheet

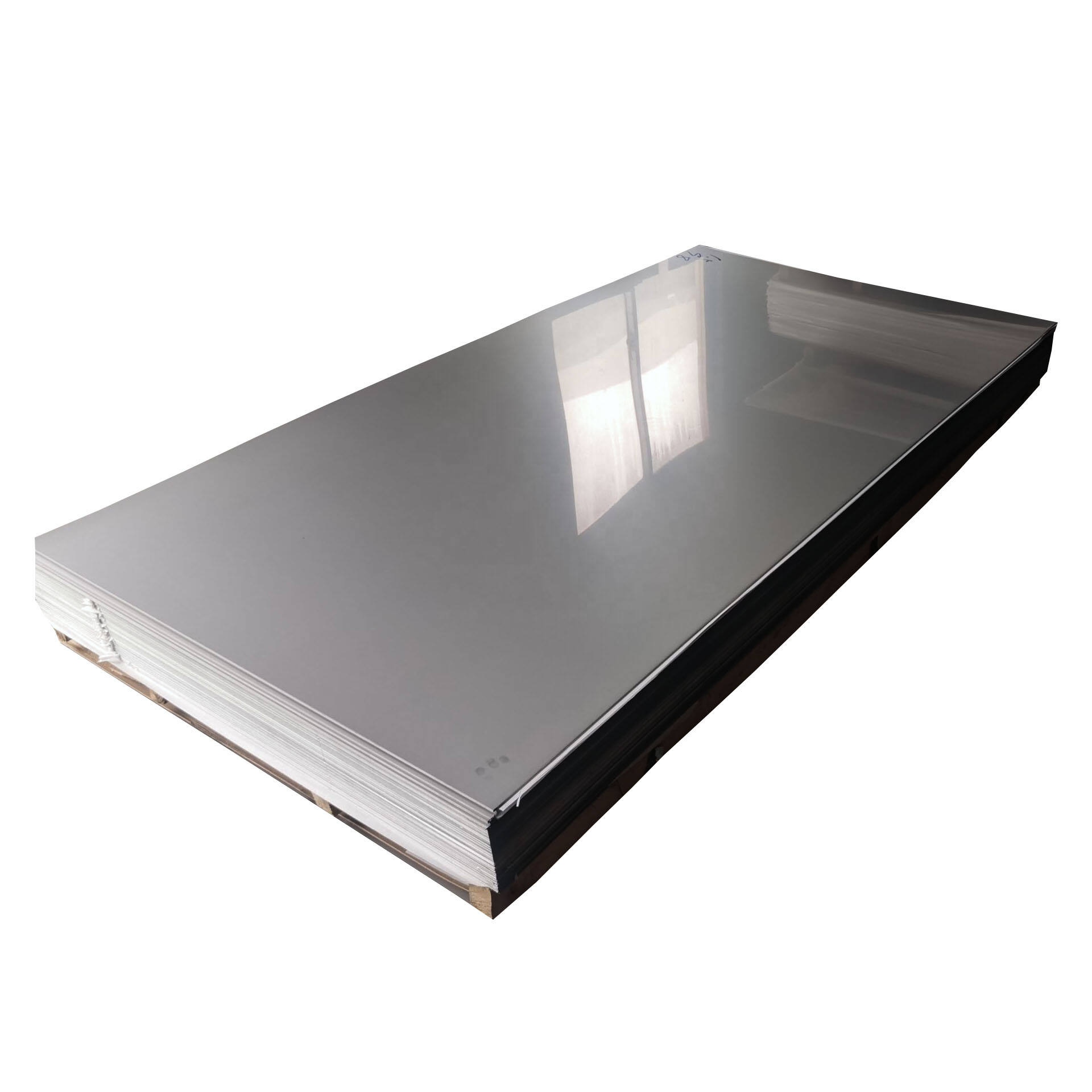

Aluminum coil sheet represents a versatile and essential industrial material, manufactured through a sophisticated rolling process that transforms raw aluminum into thin, flexible sheets wound into coils. These sheets combine lightweight properties with remarkable durability, making them invaluable across numerous industries. The manufacturing process involves precise temperature control and tension management to ensure consistent thickness and surface quality throughout the entire length of the coil. Available in various grades, tempers, and thicknesses ranging from 0.2mm to 6.0mm, aluminum coil sheets offer exceptional malleability while maintaining structural integrity. The material exhibits superior corrosion resistance due to its natural oxide layer formation, which provides an inherent protective barrier against environmental factors. These coils are engineered to meet specific industry standards and can be treated with various surface finishes, including mill finish, embossed, or coated, depending on the intended application. The continuous length of coiled material offers significant advantages in manufacturing processes, reducing material waste and improving production efficiency. Modern production techniques ensure precise dimensional accuracy and superior surface quality, making aluminum coil sheets ideal for applications ranging from construction cladding to automotive components and packaging materials.