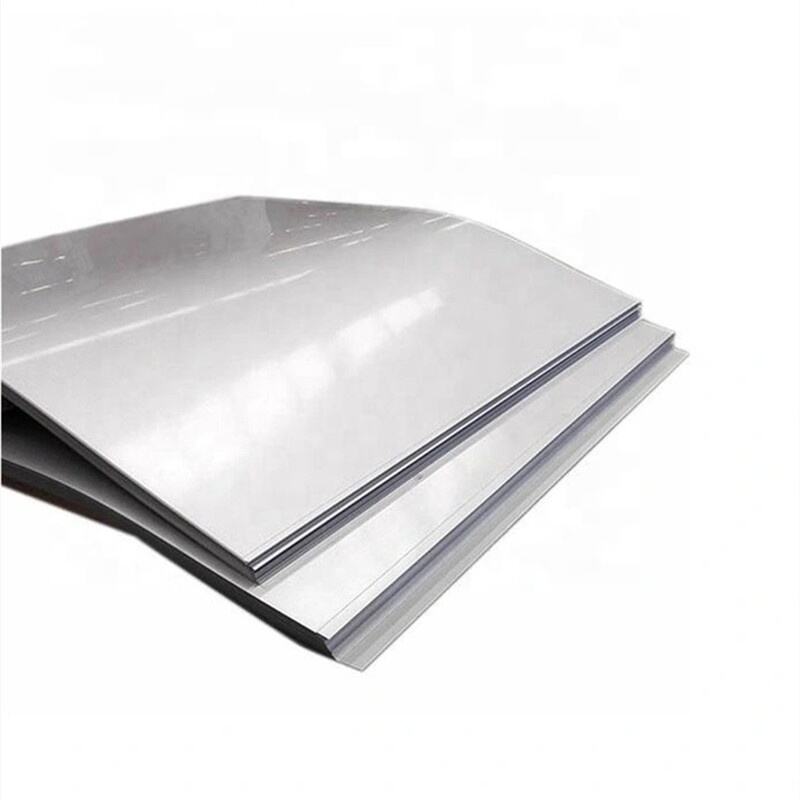

stainless steel plate manufacturers

Stainless steel plate manufacturers represent the cornerstone of modern industrial manufacturing, specializing in producing high-quality stainless steel plates that serve diverse industrial applications. These manufacturers employ cutting-edge technology and sophisticated production processes to create plates that meet stringent quality standards and specifications. Their facilities typically feature advanced rolling mills, heat treatment equipment, and precision cutting machinery to ensure consistent product quality. These manufacturers utilize various grades of stainless steel, including austenitic, ferritic, and martensitic, to produce plates with specific characteristics suited to different applications. The manufacturing process involves careful control of chemical composition, temperature, and mechanical processing to achieve desired properties such as corrosion resistance, strength, and durability. Quality control measures include ultrasonic testing, chemical analysis, and mechanical testing to verify plate integrity and conformance to international standards. Modern manufacturers also implement automated systems and computer-controlled processes to maintain precise dimensional tolerances and surface finish requirements. Their expertise extends to custom fabrication, offering plates in various sizes, thicknesses, and finishes to meet specific customer requirements across industries such as construction, aerospace, automotive, and chemical processing.