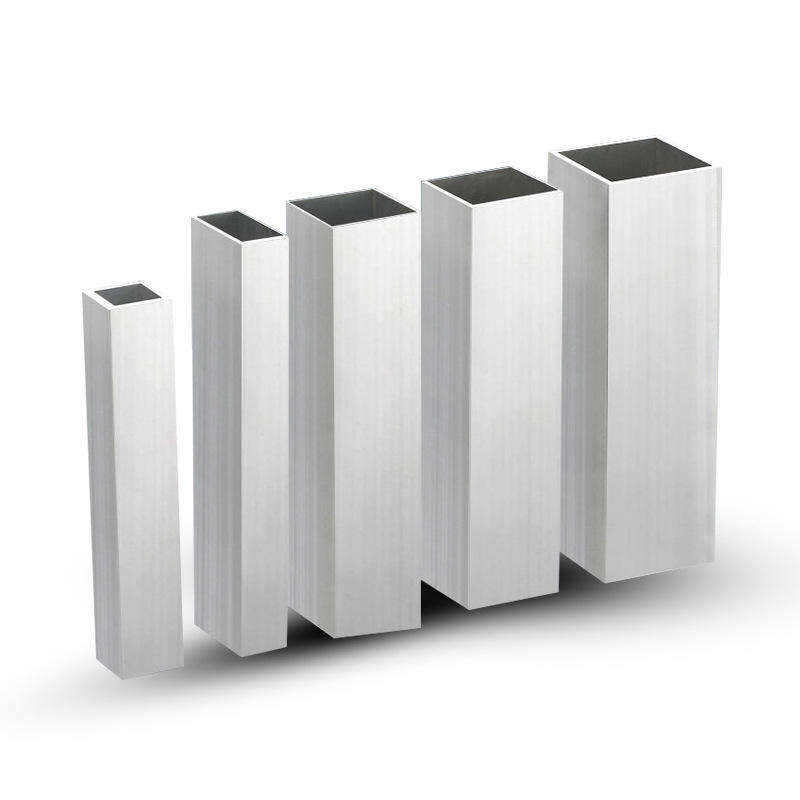

good stainless steel bar

Stainless steel bars represent a cornerstone in modern industrial and construction applications, offering unparalleled durability and versatility. These precision-engineered components are manufactured through advanced metallurgical processes, combining iron with chromium and other alloying elements to create a material that resists corrosion, oxidation, and wear. The bars come in various grades, profiles, and dimensions, making them suitable for diverse applications across multiple industries. Their exceptional mechanical properties include high tensile strength, excellent ductility, and superior heat resistance, enabling them to maintain structural integrity under extreme conditions. The manufacturing process involves careful quality control measures, ensuring consistent material properties throughout the bar length. These bars undergo rigorous testing for chemical composition, mechanical properties, and surface quality, guaranteeing reliability in critical applications. Their versatility extends from structural support in construction to precision components in machinery, medical instruments, and automotive parts. The surface finish can be customized to meet specific requirements, ranging from rough industrial finish to mirror-polished surfaces for aesthetic applications.