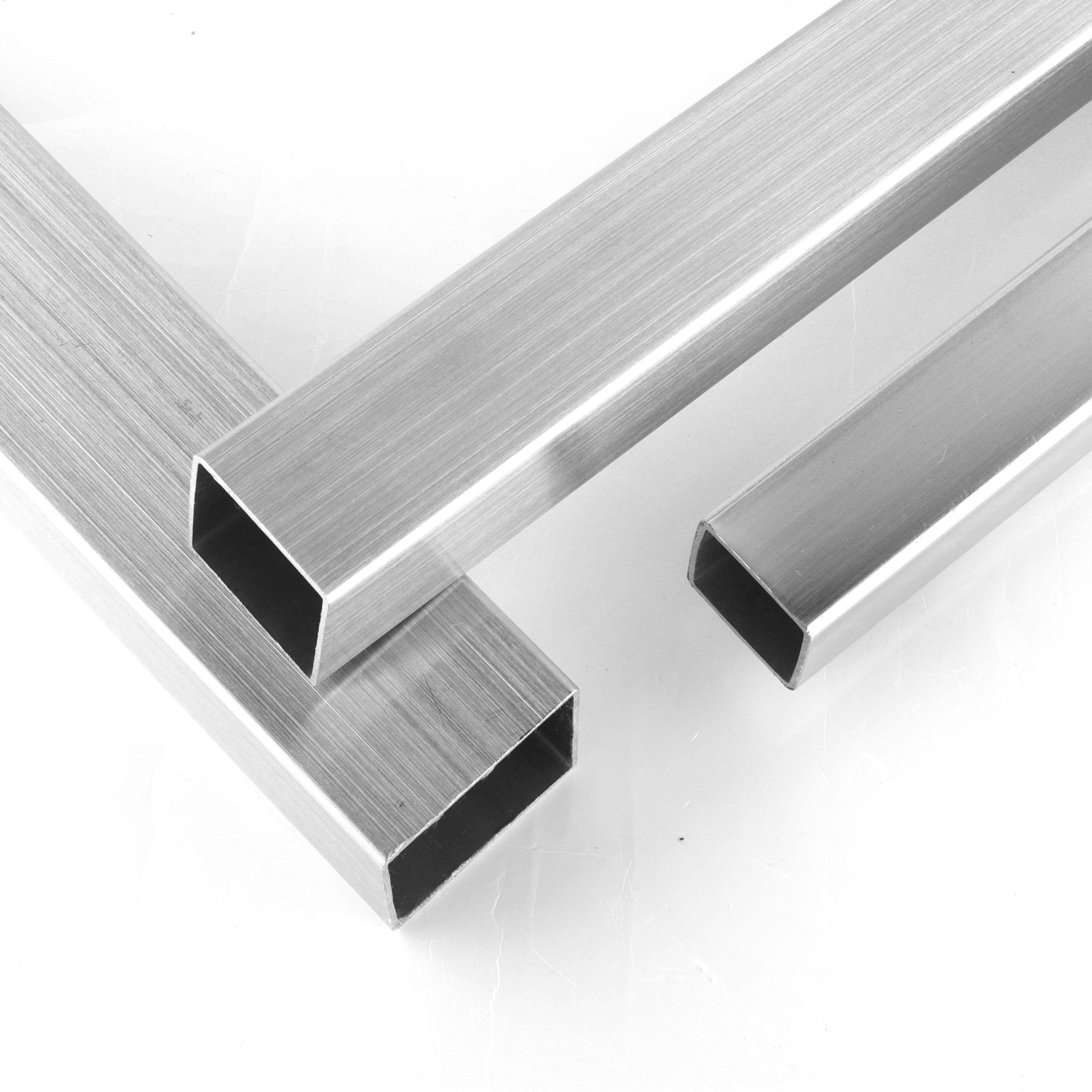

stainless steel rectangular bar

Stainless steel rectangular bars represent a versatile and robust industrial material that combines strength, durability, and corrosion resistance in a standardized format. These precision-engineered components are manufactured through advanced metallurgical processes, ensuring consistent quality and dimensional accuracy across their entire length. The bars feature a uniform rectangular cross-section, making them ideal for various structural and mechanical applications. Available in multiple grades including 304, 316, and 430, these bars offer different levels of corrosion resistance and mechanical properties to suit specific industry requirements. The manufacturing process involves hot rolling or cold drawing methods, followed by precise finishing operations to achieve the desired surface quality and dimensional tolerances. These rectangular bars are characterized by their excellent machinability, allowing for easy cutting, welding, and fabrication into various components. The material's inherent resistance to oxidation and chemical corrosion makes it particularly valuable in challenging environments where material integrity is crucial. Their standardized dimensions and consistent mechanical properties make them an essential component in engineering projects, architectural applications, and manufacturing processes.