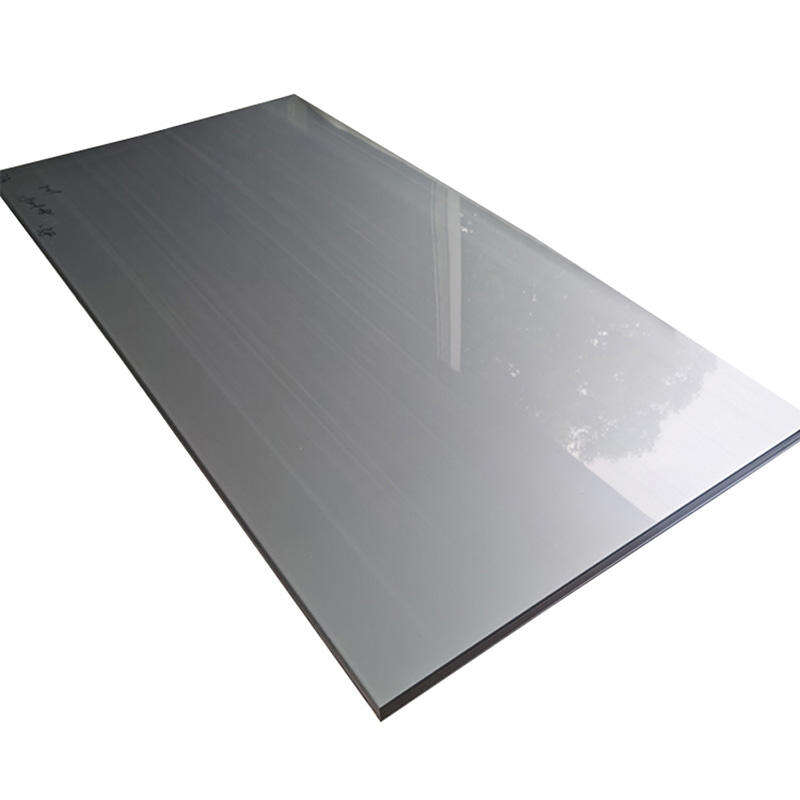

excellent stainless steel bar

Excellent stainless steel bars represent the pinnacle of metallurgical engineering, offering unparalleled quality and versatility in various industrial applications. These precision-engineered bars are manufactured using advanced production techniques that ensure consistent material properties throughout their length. The bars undergo rigorous quality control processes, including ultrasonic testing and surface inspection, to guarantee superior performance and reliability. Available in various grades, including 304, 316, and 430, these stainless steel bars exhibit exceptional corrosion resistance, impressive mechanical strength, and outstanding durability. Their uniform composition and precise dimensional accuracy make them ideal for critical applications in aerospace, automotive, construction, and medical industries. The bars feature excellent machinability, allowing for precise cutting, threading, and finishing operations while maintaining tight tolerances. Their superior surface finish reduces the need for additional processing, resulting in cost-effective manufacturing solutions. The excellent stainless steel bars also demonstrate remarkable heat and chemical resistance, making them suitable for challenging environmental conditions and aggressive chemical exposure.